Page 1864 - Flipbook_SolidDesignSoutheast2020

P. 1864

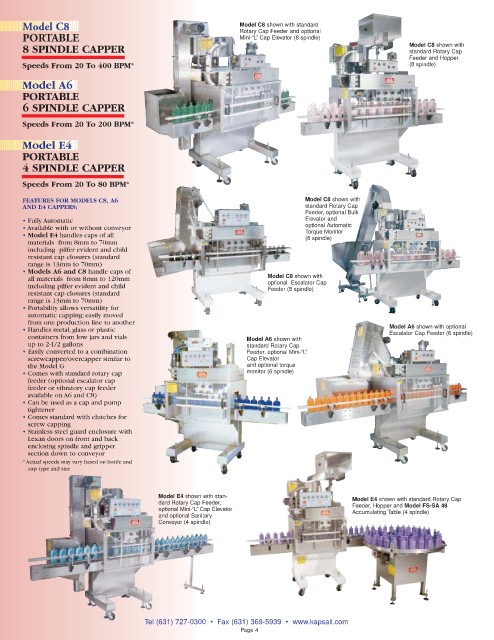

Model C8 Model C8 shown with standard

Rotary Cap Feeder and optional

PORTABLE Mini-“L” Cap Elevator (8 spindle)

8 SPINDLE CAPPER Model C8 shown with

standard Rotary Cap

Feeder and Hopper

Speeds From 20 To 400 BPM* (8 spindle)

Model A6

PORTABLE

6 SPINDLE CAPPER

Speeds From 20 To 200 BPM*

Model E4

PORTABLE

4 SPINDLE CAPPER

Speeds From 20 To 80 BPM*

FEATURES FOR MODELS C8, A6 Model C8 shown with

AND E4 CAPPERS: standard Rotary Cap

Feeder, optional Bulk

• Fully Automatic Elevator and

• Available with or without conveyor optional Automatic

Torque Monitor

• Model E4 handles caps of all (8 spindle)

materials from 8mm to 70mm

including pilfer evident and child

resistant cap closures (standard

range is 13mm to 70mm)

• Models A6 and C8 handle caps of

all materials from 8mm to 120mm Model C8 shown with

optional Escalator Cap

including pilfer evident and child Feeder (8 spindle)

resistant cap closures (standard

range is 13mm to 70mm)

• Portability allows versatility for

automatic capping; easily moved

from one production line to another

• Handles metal, glass or plastic Model A6 shown with optional

Escalator Cap Feeder (6 spindle)

containers from low jars and vials Model A6 shown with

up to 2-1/2 gallons standard Rotary Cap

• Easily converted to a combination Feeder, optional Mini-“L”

screwcapper/overcapper similar to Cap Elevator

the Model G and optional torque

• Comes with standard rotary cap monitor (6 spindle)

feeder (optional escalator cap

feeder or vibratory cap feeder

available on A6 and C8)

• Can be used as a cap and pump

tightener

• Comes standard with clutches for

screw capping

• Stainless steel guard enclosure with

Lexan doors on front and back

enclosing spindle and gripper

section down to conveyor

* Actual speeds may vary based on bottle and

cap type and size

Model E4 shown with stan- Model E4 shown with standard Rotary Cap

dard Rotary Cap Feeder, Feeder, Hopper and Model FS-SA 48

optional Mini-“L” Cap Elevator Accumulating Table (4 spindle)

and optional Sanitary

Conveyor (4 spindle)

Tel (631) 727-0300 • Fax (631) 369-5939 • www.kapsall.com

Page 4