Page 2314 - Flipbook_SolidDesignSoutheast2020

P. 2314

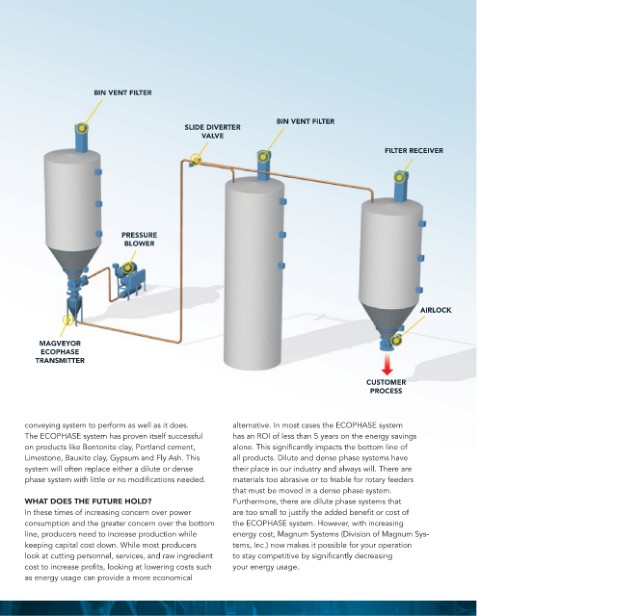

BIN VENT FILTER

BIN VENT FILTER

Ecophase Systems SLIDE DIVERTER

• Reduced energy consumption VALVE

• Maximizes the best attributes of dilute and dense FILTER RECEIVER

phase conveying

• Constant delivery of material

Magveyor

• Unique Magnum Systems technology

• Patented

• Continuous feed

• No ASME code vessel required PRESSURE

• High solids loadings BLOWER

• Lower velocities

• Minimal material degradation

AIRLOCK

MAGVEYOR

ECOPHASE

TRANSMITTER

CUSTOMER

PROCESS

THE NEW WAY OF THINKING

Since 1960, Magnum Systems has consistently brought While using the existing 4 inch convey line and blower conveying system to perform as well as it does. alternative. In most cases the ECOPHASE system

innovation to the pneumatic conveying industry. Most package, it was able to double the transfer rate of the The ECOPHASE system has proven itself successful has an ROI of less than 5 years on the energy savings

recently, Magnum Systems invested in a Research and system with the only change in the existing hardware on products like Bentonite clay, Portland cement, alone. This significantly impacts the bottom line of

Development program to develop and patent a process being a slowing down of the blower package. The Limestone, Bauxite clay, Gypsum and Fly Ash. This all products. Dilute and dense phase systems have

that takes the positive aspects from dilute phase, dense ECOPHASE system itself is centered on Magnum system will often replace either a dilute or dense their place in our industry and always will. There are

phase, and semi-dense phase systems while at the same Systems’s Magveyor, which is part of a patented process phase system with little or no modifications needed. materials too abrasive or to friable for rotary feeders

time eliminating their inherent inefficiencies. The result that uses a continuous feeding device to feed material that must be moved in a dense phase system.

was the ECOPHASE pneumatic conveying system. This into a small vessel. This vessel is equipped with the WHAT DOES THE FUTURE HOLD? Furthermore, there are dilute phase systems that

system uses a small low pressure (<14.7 PSIG) vessel, necessary level controls to ensure the material is at a In these times of increasing concern over power are too small to justify the added benefit or cost of

a continuous feeding mechanism, air supplied by a PD desired level in the vessel. The material level in the consumption and the greater concern over the bottom the ECOPHASE system. However, with increasing

blower, and an air flow management system, that when vessel is kept to a constant level to insure that air, line, producers need to increase production while energy cost, Magnum Systems (Division of Magnum Sys-

combined, reduces the amount of horsepower required from the air management system, and the material are keeping capital cost down. While most producers tems, Inc.) now makes it possible for your operation

by up to 30%. An ECOPHASE system was installed adequately mixed insuring optimum fluidization of the look at cutting personnel, services, and raw ingredient to stay competitive by significantly decreasing

to retrofit an existing 800 ft. limestone dilute phase product. This is what allows the ECOPHASE pneumatic cost to increase profits, looking at lowering costs such your energy usage.

transfer system that was struggling to make rate. as energy usage can provide a more economical