Page 2816 - Flipbook_SolidDesignSoutheast2020

P. 2816

A stable filled bag that is the outcome of safe, accurate and dust free filling BASE OPTIONS

The fill station base typically consists of a platform top or roller conveyor depending on the application requirements. Densification options are available to be integrated

equipment is always going to be the end result of NBE’s critical material either base style.

handling design factors. However, NBE’s Forward Thinking philosophy brings

bulk bag filling design up to the process integration level. The wide variety of customers’ bag styles, specific material Platform top - provides a Roller conveyor- allows the Densification table - a

base mounted adjustable

indexing of bulk bags into and

stable flat surface for the

characteristics, process demands and application constraints has driven NBE to design a comprehensive range of bulk bag bag, slip sheet or pallet out of the fill station to be vibratory densification

filler options. By looking upstream into your system, we will apply our vast materials and process knowledge to configure to sit on during the filling automated for more efficient system is designed to

settle the product in the

all the required filler features that will optimize your system’s performance and budget. From the simplest Bulk Bag Filler sequence filling cycles. bag during the filling cycle

to a completely automated system, the Real Results obtained every day by NBE’s customers include: increased throughput to produce a more dense

and productivity; improved system controls integration; reduced operating costs through savings in direct labor and and square package. The

high amplitude, medium frequency vibration is isolated from

material loss due to inaccurate filling equipment and excessive dusting. the main framework by airbags during operation.

FILL HEAD DETAILS

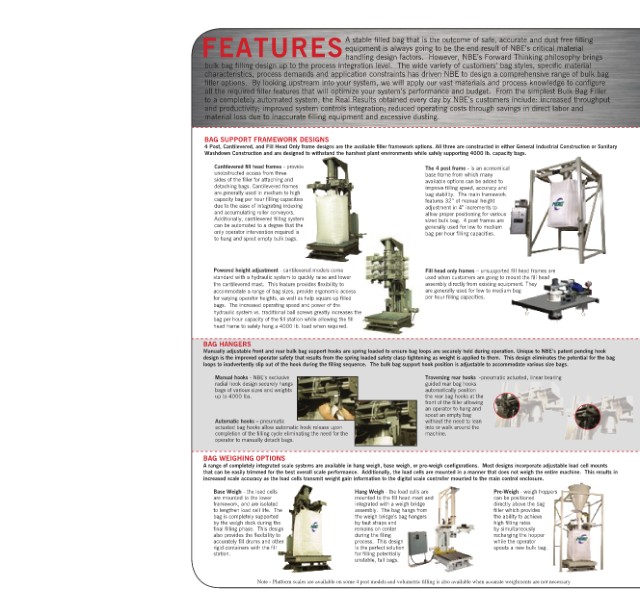

BAG SUPPORT FRAMEWORK DESIGNS The fill head assembly system includes a concentric tube design that has an 8” diameter product feed tube located within a 12” diameter outer fill spout. The feed tube is

4 Post, Cantilevered, and Fill Head Only frame designs are the available filler framework options. All three are constructed in either General Industrial Construction or Sanitary connected to the outer tube with

Washdown Construction and are designed to withstand the harshest plant environments while safely supporting 4000 lb. capacity bags. optional bag inflation devices, and a 3” exhaust vent port.

Cantilevered fill head frames - provide The 4 post frame - is an economical Blower - a 1 HP electric blower package provides Concentric tubes – an annular gap between the Inflatable bladder - an inflatable

unobstructed access from three base frame from which many rapid bag inflation concentric tubes on the fill head bladder holds and seals the

sides of the filler for attaching and available options can be added to prior to filling material allows air from the blower to bag spout ensuring dust free

detaching bags. Cantilevered frames improve filling speed, accuracy and in order to properly enter during bag inflation and operation. A manual Inflate/

are generally used in medium to high bag stability. The main framework shape the bag for displaced air and dust to exit Deflate selector switch is located

capacity bag per hour filling capacities features 32” of manual height maximum stability during bag filling. on the upper carriage for ease of

due to the ease of integrating indexing adjustment in 4” increments to and filling capacity. spouting the bulk bag to the fill head.

and accumulating roller conveyors. allow proper positioning for various

Additionally, cantilevered filling system sized bulk bag. 4 post frames are

can be automated to a degree that the generally used for low to medium Dust collection – an Drum & box fill adapters – are available options that Material flow control valves -bulk and dribble feed rates

only operator intervention required is bag per hour filling capacities. air displacement outlet allow the conversion from filling bags to can be achieved by utilizing pneumatic actuated slide

to hang and spout empty bulk bags. allows for connection filling drums and other rigid gates or other types of

to a dust collector containers. Adapters easily valves based on material

system, vent sock, or mount to the existing fill head for flow characteristics and

filter cartridge. accurate and dust free filling. application requirements.

Powered height adjustment - cantilevered models come Fill head only frames – unsupported fill head frames are

standard with a hydraulic system to quickly raise and lower used when customers are going to mount the fill head Traversing fill head -the fill Hanging and spouting the bag with the fill Once the bag is attac

the cantilevered mast. This feature provides flexibility to assembly directly from existing equipment. They spout traverses forward from head mast in a horizontal orientation, as cantilevered mast the ope

accommodate a range of bag sizes, provide ergonomic access are generally used for low to medium bag the machine center toward the apposed to vertically, provides the quickest start fill button to automatic

for varying operator heights, as well as help square up filled per hour filling capacities. operator. This brings all bag and easiest method for spouting new the bag in the ideal bag fill location

bags. The increased operating speed and power of the and operator interface bags. New bags are stiff and typically while inflating it to remove any

hydraulic system vs. traditional ball screws greatly increases the points well within folded length-wise which makes creases. The end result is the most

bag per hour capacity of the fill station while allowing the fill arms length for ease of them difficult to handle in a vertical ergonomic, efficient and accurate

head frame to safely hang a 4000 lb. load when required. spouting the bag inlet. spouting orientation. bag fill station.

BAG HANGERS CONTROL SYSTEMS

Manually adjustable front and rear bulk bag support hooks are spring loaded to ensure bag loops are securely held during operation. Unique to NBE’s patent pending hook An assortment of control options ranging fr

design is the improved operator safety that results from the spring loaded safety clasp tightening as weight is applied to them. This design eliminates the potential for the bag equipment. The controls can be

loops to inadvertently slip out of the hook during the filling sequence. The bulk bag support hook position is adjustable to accommodate various size bags.

Manual and semi-automatic Automatic systems - utilize Height adjustment - a linear

Manual hooks - NBE’s exclusive Traversing rear hooks -pneumatic actuated, linear bearing systems - utilize a a programmable PLC and transducer provides infinite

radial hook design securely hangs guided rear bag hooks combination of manual panelview HMI to automate the adjustability for the cantivered

bags of various sizes and weights automatically position

up to 4000 lbs. the rear bag hooks at the switches and digital filler sequence of operations. mast within the 36” range of

front of the filler allowing scale controller I/O to Tasks that are typically automated travel. Height setpoints are easily

an operator to hang and complete the bag fill include moving the traversing fill entered into the HMI eliminating

spout an empty bag sequence of operations. head and hooks forward and back, the need to manually adjust

Automatic hooks – pneumatic without the need to lean All operator settings and raising and lowering bag, inflating position switches on the machine.

actuated bag hooks allow automatic hook release upon into or walk around the controls, including the bag, filling bag, densifying bag, releasing hooks, closing slide

completion of the filling cycle eliminating the need for the machine. scale settings, can be accomplished gate, starting and stopping upstream conveyors, deflating

operator to manually detach bags. through the HMI. seal and indexing the filled bag out of the fill station.

BAG WEIGHING OPTIONS COMMON CONFIGURATIONS NBE manufactures the most rugged, user friendly, feature rich, bulk bag fillers

A range of completely integrated scale systems are available in hang weigh, base weigh, or pre-weigh configurations. Most designs incorporate adjustable load cell mounts available anywhere. From simple manual fil

that can be easily trimmed for the best overall scale performance. Additionally, the load cells are mounted in a manner that does not weigh the entire machine. This results in NBE’s comprehensive range of opti

increased scale accuracy as the load cells transmit weight gain information to the digital scale controller mounted to the main control enclosure.

common configurations of available options that meet the needs of many customers.

Base Weigh - the load cells Hang Weigh - the load cells are Pre-Weigh - weigh hoppers Configuration 1: economical 4 post frame Configuration 2: economical 4 post Configuration 3: ergonomic cantilevered C

are mounted to the lower mounted to the fill head mast and can be positioned

framework, and are isolated integrated with a weigh bridge directly above the bag with base weigh scale system frame with hang weigh scale system frame with base weigh scale frame with hang

to lengthen load cell life. The assembly. The bag hangs from filler which provides for low to medium capacity for low to medium capacity system and automatic weigh scale system

bag is completely supported the weigh bridge’s bag hangers the ability to achieve bag and box filling of bag filling of controls for medium to and semi

by the weigh deck during the by taut straps and high filling rates materials that require materials that high capacity bag, automatic

final filling phase. This design remains on center by simultaneously densification. do not require drum and box controls for

also provides the flexibility to during the filing recharging the hopper densification. filling of materials medium to

accurately fill drums and other process. This design while the operator that require high capacity bag

rigid containers with the fill is the perfect solution spouts a new bulk bag.

station. for filling potentially densification. filling of materials that

unstable, tall bags. do not require

densification.

Note - Platform scales are available on some 4 post models and volumetric filling is also available when accurate weighments are not necessary

National bulk equipment 616-399-2220 • forward thinking. Real results.