Page 2967 - Flipbook_SolidDesignSoutheast2020

P. 2967

Always at the forefront

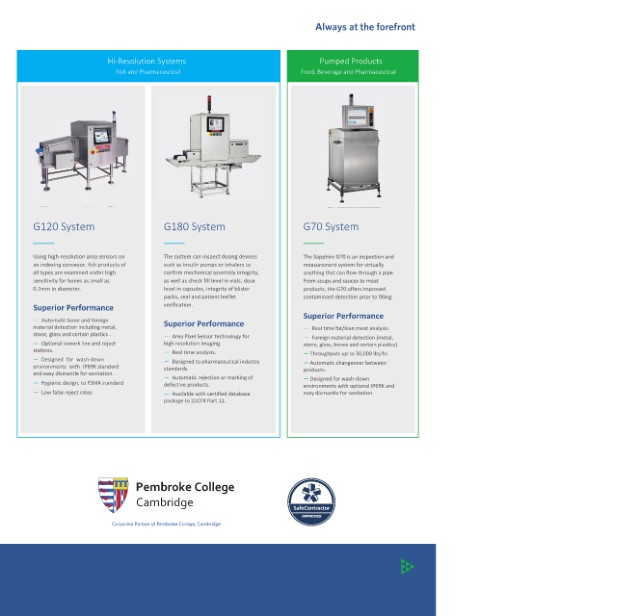

Entry Level Systems Conveyor Systems Hi-Resolution Systems Pumped Products

Food and Pharmaceutical Food, Beverage and Pharmaceutical Fish and Pharmaceutical Food, Beverage and Pharmaceutical

A Series G20 System G40/G80 System G120 System G180 System G70 System

A sophisticated and economic entry These systems can be configured for a Designed for large packaged products Using high-resolution area sensors on The system can inspect dosing devices The Sapphire G70 is an inspection a

level x-ray inspection system for wide range of products from packaged and wide unpackaged bulk-product an indexing conveyor, fish products of such as insulin pumps or inhalers to measurement system for virtually

automatic, end-of-line inspection. items to unpackaged bulk-product flows the Sapphire G40 and G80 are all types are examined under high confirm mechanical assembly integrity, anything that can flow through a pipe.

Compact enough to fit into an existing flows. Superior foreign material state of the art, high-speed inspection sensitivity for bones as small as as well as check fill level in vials, dose From soups and sauces to meat

production line, the A Series from detection including metal, bone, systems. Offering superior foreign 0.2mm in diameter. level in capsules, integrity of blister products, the G70 offers improved

Sapphire can inspect small to mid-size stone, glass and certain plastics as well material detection including metal, packs, seal and patient leaflet contaminant detection prior to filling.

packaged product. as product conformity checks. bone, stone, glass and certain plastics Superior Performance verification.

as well as product conformity checks. Superior Performance

material detection including metal,

Superior Performance Superior Performance Superior Performance — Automatic bone and foreign Superior Performance — Real time fat/lean meat analysis.

stone, glass and certain plastics .

Foreign material detection (metal, — Flexible layout available in multiple — Optional rework line and reject — Area Pixel Sensor technology for — Foreign material detection (metal,

high resolution imaging.

configurations.

stone, glass, bone and certain plastics) — Optional IP69K design — Custom systems with apertures up stations. — Real time analysis. stone, glass, bones and certain plastics).

to 614mm wide x 614mm high.

— Scan for mass, missing or broken — wash-down — Throughputs up to 30,000 lbs/hr.

product. — Hygienic design, to FSMA standard — Hygienic design, to FSMA standard IP69K standard — Designed to pharmaceutical industry — Automatic changeover between

— Detect voids — 400-fpm — Optional IP69K design and easy dismantle for sanitation. standards. products.

— Rates up to 150-fpm — Multi-lane inspection — Rates up to 400-fpm — Hygienic design, to FSMA standard — Automatic rejection or marking of — Designed for wash-down

defective products.

environments with optional IP69K and

— Automatic calibration — Seal verification option — Multi-lane inspection Low false reject rates — Available with certified database easy dismantle for sanitation.

— Curtain-free option — Curtain-free option package to 21CFR Part 11.

Sapphire SAC – Always at the forefront

Renowned as the innovators of low energy inspection, Sapphire Inspection Systems have

over 40 years experience in the development, manufacture and application of x-ray

inspection systems and core x-ray components.

Innovative X-Ray Inspection.

Smarter Product Solutions.