Page 3171 - Flipbook_SolidDesignSoutheast2020

P. 3171

TechnicalExclusive

32

Januar y 2019

What You Need to Know

About Combustible Dust

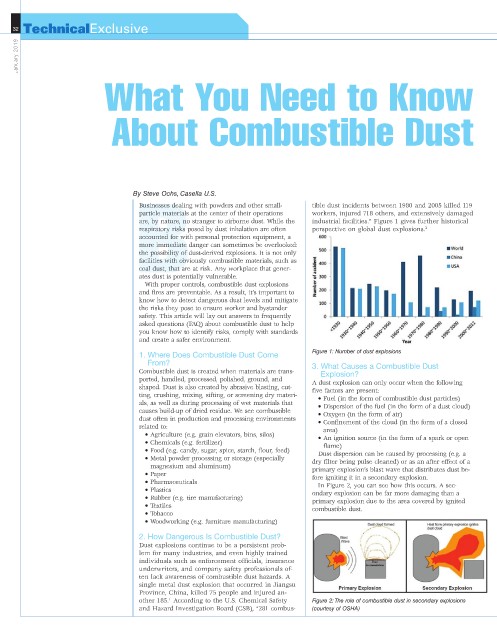

By Steve Ochs, Casella U.S. tible dust incidents between 1980 and 2005 killed 119

Businesses dealing with powders and other small-

B industrial facilities.” Figure 1 gives further historical

workers, injured 718 others, and extensively damaged

particle materials at the center of their operations

are, by nature, no stranger to airborne dust. While the

2

perspective on global dust explosions.

respiratory risks posed by dust inhalation are often

accounted for with personal protection equipment, a

more immediate danger can sometimes be overlooked:

the possibility of dust-derived explosions. It is not only

facilities with obviously combustible materials, such as

coal dust, that are at risk. Any workplace that gener-

ates dust is potentially vulnerable.

With proper controls, combustible dust explosions

and fires are preventable. As a result, it’s important to

know how to detect dangerous dust levels and mitigate

the risks they pose to ensure worker and bystander

safety. This article will lay out answers to frequently

asked questions (FAQ) about combustible dust to help

you know how to identify risks, comply with standards

and create a safer environment.

Figure 1: Number of dust explosions

1. Where Does Combustible Dust Come

From? 3. What Causes a Combustible Dust

Combustible dust is created when materials are trans- Explosion?

ported, handled, processed, polished, ground, and

A dust explosion can only occur when the following

shaped. Dust is also created by abrasive blasting, cut-

five factors are present:

ting, crushing, mixing, sifting, or screening dry materi-

• Fuel (in the form of combustible dust particles)

als, as well as during processing of wet materials that

• Dispersion of the fuel (in the form of a dust cloud)

causes build-up of dried residue. We see combustible

• Oxygen (in the form of air)

dust often in production and processing environments

• Confinement of the cloud (in the form of a closed

related to:

area)

• Agriculture (e.g. grain elevators, bins, silos)

• An ignition source (in the form of a spark or open

• Chemicals (e.g. fertilizer)

flame)

• Food (e.g. candy, sugar, spice, starch, flour, feed)

Dust dispersion can be caused by processing (e.g. a

• Metal powder processing or storage (especially

dry filter being pulse cleaned) or as an after effect of a

magnesium and aluminum)

primary explosion’s blast wave that distributes dust be-

• Paper

fore igniting it in a secondary explosion.

• Pharmaceuticals

In Figure 2, you can see how this occurs. A sec-

• Plastics

ondary explosion can be far more damaging than a

• Rubber (e.g. tire manufacturing)

primary explosion due to the area covered by ignited

• Textiles

combustible dust.

• Tobacco

• Woodworking (e.g. furniture manufacturing)

2. How Dangerous Is Combustible Dust?

Dust explosions continue to be a persistent prob-

lem for many industries, and even highly trained

individuals such as enforcement officials, insurance

underwriters, and company safety professionals of-

ten lack awareness of combustible dust hazards. A

single metal dust explosion that occurred in Jiangsu

Province, China, killed 75 people and injured an-

other 185. According to the U.S. Chemical Safety Figure 2: The role of combustible dust in secondary explosions

1

and Hazard Investigation Board (CSB), “281 combus- (courtesy of OSHA)