Page 187 - FAT 105 4.17 MOODLE

P. 187

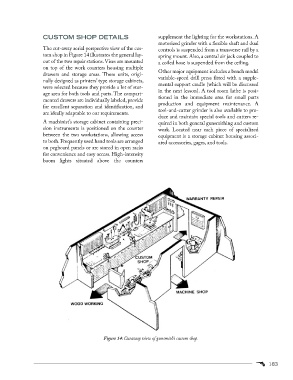

CUSTOM SHOP DETAILS supplement the lighting for the workstations. A

motorized grinder with a flexible shaft and dual

The cut-away aerial perspective view of the cus- controls is suspended from a transverse rail by a

tom shop in Figure 14 illustrates the general lay- spring mount. Also, a central air jack coupled to

out of the two repair stations. Vises are mounted a coiled hose is suspended from the ceiling.

on top of the work counters housing multiple

Other major equipment includes a bench model

drawers and storage areas. These units, origi-

variable-speed drill press fitted with a supple-

nally designed as printers’ type storage cabinets,

mental support cradle (which will be discussed

were selected because they provide a lot of stor-

in the next lesson). A tool room lathe is posi-

age area for both tools and parts. The compart-

tioned in the immediate area for small parts

mented drawers are individually labeled, provide

production and equipment maintenance. A

for excellent separation and identification, and

tool-and-cutter grinder is also available to pro-

are ideally adaptable to our requirements.

duce and maintain special tools and cutters re-

A machinist’s storage cabinet containing preci- quired in both general gunsmithing and custom

sion instruments is positioned on the counter work. Located near each piece of specialized

between the two workstations, allowing access equipment is a storage cabinet housing associ-

to both. Frequently used hand tools are arranged ated accessories, gages, and tools.

on pegboard panels or are stored in open racks

for convenience and easy access. High-intensity

boom lights situated above the counters

Figure 14: Cutaway view of gunsmith’s custom shop.

183