Page 23 - S:\tracie.delicata\Documents\Marketing\Brochures.Manuals\ButekLandlineBrochure2018\ButekLandlineBrochure2018 Folder\

P. 23

Call Us Today: +44 (0) 1277 653 281

Case Study: Laggan Tormore - Steel Demountable Tanks with Impermeable Liners The liquidtight liners for these tanks were manufactured in our UK factory to the high standards required for the

petrochemical industry and military / Emergency Aid specifications.

The liner selected was 1.00mm Butyl Rubber with grade A recommended chemical resistance to the

Mono-Ethylene Glycol to be stored. Bespoke Butyl rubber sleeves were designed and supplied to protect the

galvanised iron roof supports from the tank contents.

The tank roofs were designed to be transportable in kit form and were supplied complete with lockable

inspection manways.

The tanks have five decades of service history and have been widely deployed in the UK and overseas, wherever

secure storage of liquids is required for short or long term.

Project: Supply & Install Glycol Storage Tanks for Laggan Tormore North Sea Gas Terminal

Client: Halliburton Pipeline & Process Services on behalf of Petrofac Ltd.

Summary: The new Laggan Tormore Gas terminal had a requirement for 4,500,000 litres of Ethylene Glycol to be safely stored

on a temporary basis. Design considerations included:

• Containment of the Glycol through choice of appropriate lining material

• Environmental standards to be very high as agreed with Shetland Islanders

• Rapid deployment required to meet project critical path

• Safe removal of all eqipment when main storage facility came online

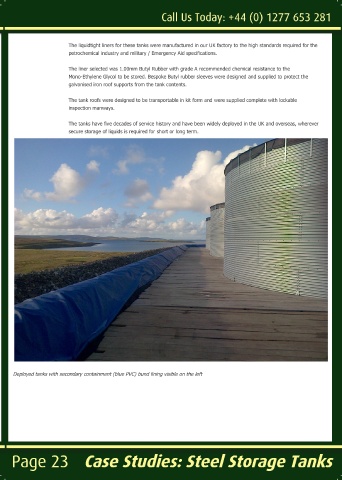

Challenges: Special consideration was given to the adverse weather conditions frequently experienced in the Shetland Isles, Deployed tanks with secondary containment (blue PVC) bund lining visible on the left

high winds, heavy rainfall and snow.

The tank structure was uprated to accommodate this, with a steel roof option also designed to resist the weather

conditions, particularly snow loading.

Our Solution: The tanks offered have a structure built from galvanised, corrugated steel panels which are curved to form the

required diameter and punched to accommodate the correct number and layout of fixings to meet EU standards for

this type of storage tank.

Each of the 9 tanks measured 11.98m diameter x 4.60m high to meet the capacity requirement.

Page 23 Case Studies: Steel Storage Tanks