Page 25 - S:\tracie.delicata\Documents\Marketing\Brochures.Manuals\ButekLandlineBrochure2018\ButekLandlineBrochure2018 Folder\

P. 25

Call Us Today: +44 (0) 1277 653 281

Case Study: A5 to M1 Link - Attenuation Ponds Case Study: Gas Membrane & designed Gas Venting system

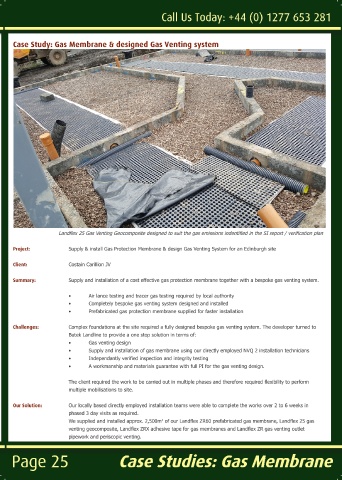

Landflex 25 Gas Venting Geocomposite designed to suit the gas emissions indentified in the SI report / verification plan

A5 - M1 link road and new M11 junction 11A: Photo by Highways England

Project: Supply & install Gas Protection Membrane & design Gas Venting System for an Edinburgh site

Project: Supply & install attenuation pond linings around the new link site.

Client: Costain Carillion JV

Client: Costain Carillion JV

Summary: Supply and installation of a cost effective gas protection membrane together with a bespoke gas venting system.

Summary: Supply and installation of seven impermeable membranes to attenuation ponds around the site.

• Air lance testing and tracer gas testing required by local authority

• Excavation of anchor trenches • Completely bespoke gas venting system designed and installed

• Installation of Landflex PE100LL liner system to all seven ponds • Prefabricated gas protection membrane supplied for faster installation

• Placement of fill over installed liner system

Challenges: Complex foundations at the site required a fully designed bespoke gas venting system. The developer turned to

Challenges: Maintain integrity of the installation and enable storm / rainwater run-off to be captured in the attenuation ponds, Butek Landline to provide a one stop solution in terms of:

thereby avoiding overloading of the drainage system. • Gas venting design

• Supply and installation of gas membrane using our directly employed NVQ 2 installation technicians

Our Solution: A geosynthetic clay liner was originally specified by the clients project engineers but our Landflex PE100LL proved • Independantly verified inspection and integrity testing

to be the preferred choice for this installation due to its durability, long lifetime and tensile strength. • A workmanship and materials guarantee with full PI for the gas venting design.

The lining system, comprising Landflex PE100LL together with protective geotextiles and soil placement covered a

total area of 21,000m and was completed in 30 days. The client required the work to be carried out in multiple phases and therefore required flexibility to perform

2

multiple mobilisations to site.

Landflex PE100LL is an inert UV resistant material. Once installed and covered it has an expected design lifetime in

excess of 50 years. It is an extremely cost effective solution for projects of this nature. Our Solution: Our locally based directly employed installation teams were able to complete the works over 2 to 6 weeks in

phased 3 day visits as required.

The installation of Landflex PE membranes has a proven track record over 30 years in attenuation pond lining We supplied and installed approx. 2,500m of our Landflex ZR60 prefabricated gas membrane, Landflex 25 gas

2

for road schemes. Its ability to be welded on site and tailored to the excavation allow for speedy and efficient venting geocomposite, Landflex ZRX adhesive tape for gas membranes and Landflex ZR gas venting outlet

installation. Fully welded and CQA tested for integrity; the client is assured of a totally watertight solution. pipework and periscopic venting.

Page 25 Case Studies: Gas Membrane