Page 237 - The ROV Manual - A User Guide for Remotely Operated Vehicles 2nd edition

P. 237

226 CHAPTER 9 LARS and TMS

systems with a TMS, the cage umbilical is normally made of durable material (steel, Kevlar, etc.) with the conductors for the vehicle buried within the core of the umbilical. For deeper diving sub- mersibles, the umbilical encases fiber-optic data links to the cage, requiring digital modem feeds from the cage to the control unit at the surface. For a more detailed discussion of currents and tether management see Section 9.3.

9.2 TMS-based vehicle deployment techniques

The larger ROVs may have more power available at the vehicle, but that just translates to these being able to get into bigger, costlier problems. To ensure safe launch and recovery through the ocean surface, several techniques have been developed. Most of these techniques depend upon the platform itself, whether it is stable (e.g., a large oil rig) or not so stable (e.g., a multipurpose service vessel, MSV). As the vessel’s dynamics increase, so does the requirement to add additional equip- ment to help counter the dynamic forces imposed by the ocean.

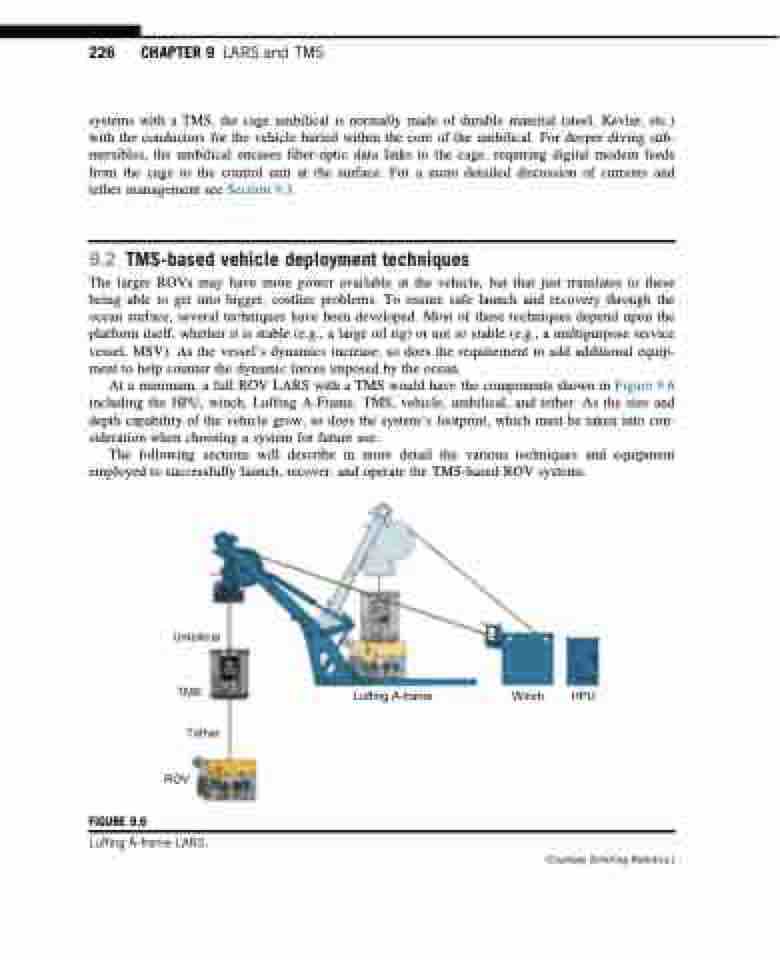

At a minimum, a full ROV LARS with a TMS would have the components shown in Figure 9.6 including the HPU, winch, Luffing A-Frame, TMS, vehicle, umbilical, and tether. As the size and depth capability of the vehicle grow, so does the system’s footprint, which must be taken into con- sideration when choosing a system for future use.

The following sections will describe in more detail the various techniques and equipment employed to successfully launch, recover, and operate the TMS-based ROV systems.

Umbilical

TMS Tether

ROV

Luffing A-frame LARS.

Luffing A-frame

Winch HPU

FIGURE 9.6

(Courtesy Schilling Robotics.)