Page 239 - The ROV Manual - A User Guide for Remotely Operated Vehicles 2nd edition

P. 239

228 CHAPTER 9 LARS and TMS

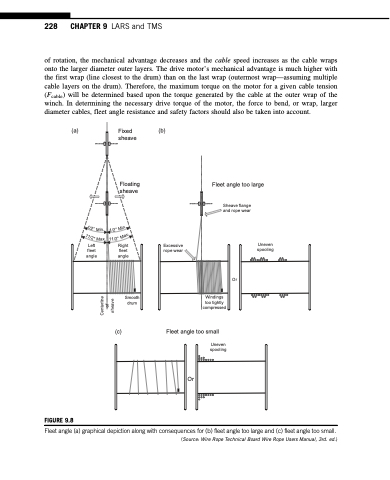

of rotation, the mechanical advantage decreases and the cable speed increases as the cable wraps onto the larger diameter outer layers. The drive motor’s mechanical advantage is much higher with the first wrap (line closest to the drum) than on the last wrap (outermost wrap—assuming multiple cable layers on the drum). Therefore, the maximum torque on the motor for a given cable tension (Fcable) will be determined based upon the torque generated by the cable at the outer wrap of the winch. In determining the necessary drive torque of the motor, the force to bend, or wrap, larger diameter cables, fleet angle resistance and safety factors should also be taken into account.

(a)

Fixed sheave

Floating sheave

Right fleet angle

Smooth drum

(c)

(b)

Fleet angle too large

Left

fleet angle

Excessive rope wear

Sheave flange and rope wear

Or

Uneven spooling

Fleet angle too small

Uneven spooling

Or

Windings

too tightly compressed

FIGURE 9.8

Fleet angle (a) graphical depiction along with consequences for (b) fleet angle too large and (c) fleet angle too small.

(Source: Wire Rope Technical Board Wire Rope Users Manual, 3rd. ed.)

n

i

.

M

°

n/

2

1

/

2

.

°

M

i

x

.

a

M

°

1

2

/

1

x

1

/

2

.

°

M

1 1

a

Centerline of sheave