Page 6 - FQ10591.PloteConstruction.IL.For-ReadyMixBatchPlant.DC15000S w5000GalTank wDuplexDelPumpPkg

P. 6

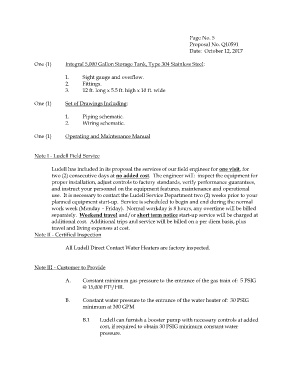

Page No. 5

Proposal No. Q10591

Date: October 12, 2017

One (1) Integral 5,000 Gallon Storage Tank, Type 304 Stainless Steel:

1. Sight gauge and overflow.

2. Fittings.

3. 12 ft. long x 5.5 ft. high x 10 ft. wide

One (1) Set of Drawings Including:

1. Piping schematic.

2. Wiring schematic.

One (1) Operating and Maintenance Manual

Note I - Ludell Field Service

Ludell has included in its proposal the services of our field engineer for one visit, for

two (2) consecutive days at no added cost. The engineer will: inspect the equipment for

proper installation, adjust controls to factory standards, verify performance guarantees,

and instruct your personnel on the equipment features, maintenance and operational

use. It is necessary to contact the Ludell Service Department two (2) weeks prior to your

planned equipment start-up. Service is scheduled to begin and end during the normal

work week (Monday – Friday). Normal workday is 8 hours, any overtime will be billed

separately. Weekend travel and/or short term notice start-up service will be charged at

additional cost. Additional trips and service will be billed on a per diem basis, plus

travel and living expenses at cost.

Note II - Certified Inspection

All Ludell Direct Contact Water Heaters are factory inspected.

Note III - Customer to Provide

A. Constant minimum gas pressure to the entrance of the gas train of: 5 PSIG

@ 15,000 FT /HR.

3

B. Constant water pressure to the entrance of the water heater of: 30 PSIG

minimum at 300 GPM

B.1 Ludell can furnish a booster pump with necessary controls at added

cost, if required to obtain 30 PSIG minimum constant water

pressure.