Page 119 - Petron Plus with Price List

P. 119

TM

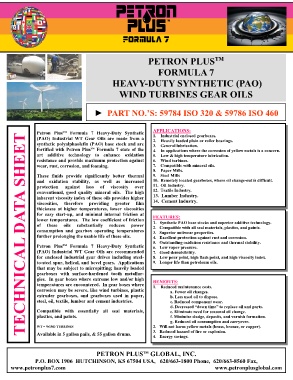

PETRON PLUS

FORMULA 7

HEAVY-DUTY SYNTHETIC (PAO)

WIND TURBINES GEAR OILS

► PART NO.’S: 59784 ISO 320 & 59786 ISO 460

APPLICATIONS:

TECHNICAL DATA SHEET

TM

Petron Plus Formula 7 Heavy-Duty Synthetic

(PAO) Industrial WT Gear Oils are made from a 1. Industrial enclosed gearboxes.

2. Heavily loaded plain or roller bearings.

synthetic polyalphaolefin (PAO) base stock and are 3. General lubrication.

fortified with Petron Plus Formula 7 state of the 4. In applications where the corrosion of yellow metals is a concern.

TM

art additive technology to enhance oxidation 5. Low & high temperature lubrication.

resistance and provide maximum protection against 6. Wind turbines.

wear, rust, corrosion, and foaming. 7. Compatible with mineral oils.

8. Paper Mills.

These fluids provide significantly better thermal 9. Steel Mills

and oxidation stability, as well as increased 10. Remotely located gearboxes, where oil change-out is difficult.

protection against loss of viscosity over 11. Oil Industry.

conventional, good quality mineral oils. The high 12. Textile Industry.

inherent viscosity index of these oils provides higher 13. Lumber Industry.

viscosities, therefore providing greater film 14. Cement Industry.

thickness at higher temperatures, lower viscosities

for easy start-up, and minimal internal friction at

lower temperatures. The low coefficient of friction FEATURES:

of these oils substantially reduces power 1. Synthetic PAO base stocks and superior additive technology.

2. Compatible with all seal materials, plastics, and paints.

consumption and gearbox operating temperatures 3. Superior antiwear properties.

further prolonging the usable life of these oils. 4. Excellent protection against rust and corrosion.

5. Outstanding oxidation resistance and thermal stability.

Petron Plus Formula 7 Heavy-Duty Synthetic 6. Low vapor pressure.

TM

(PAO) Industrial WT Gear Oils are recommended 7. Good demulsibility.

for enclosed industrial gear drives including steel- 8. Low pour point, high flash point, and high viscosity index.

to-steel spur, helical, and bevel gears. Applications 9. Longer life than petroleum oils.

that may be subject to micropitting; heavily loaded

gearboxes with surface-hardened tooth metallur-

gies. In gear boxes where extreme low and/or high BENEFITS:

temperatures are encountered. In gear boxes where 1. Reduced maintenance costs.

corrosion may be severe. like wind turbines, plastic a. Fewer oil changes.

extruder gearboxes, and gearboxes used in paper, b. Less used oil to dispose.

steel, oil, textile, lumber and cement industries. c. Reduced component wear.

d. Decreased “down time” to replace oil and parts.

Compatible with essentially all seal materials, e. Eliminate need for seasonal oil change.

plastics, and paints. f. Minimize sludge, deposits, and varnish formation.

g. Reduced oil consumption and carryover.

WT = WIND TURBINES 2. Will not harm yellow metals (brass, bronze, or copper).

3. Reduced hazard of fire or explosion.

Available in 5 gallon pails, & 55 gallon drums. 4. Energy savings.

PETRON PLUS GLOBAL, INC.

TM

P.O. BOX 1906 HUTCHINSON, KS 67504 USA, 620/663-1800 Phone, 620/663-8560 Fax,

www.petronplus7.com www.petronplusglobal.com