Page 10 - C:\Users\Adik\Documents\Flip PDF Professional\Marketer PPT LR\

P. 10

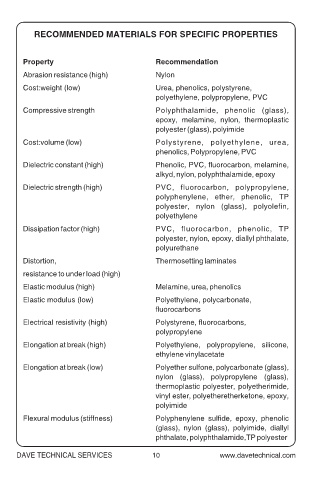

RECOMMENDED MATERIALS FOR SPECIFIC PROPERTIES

Property Recommendation

Abrasion resistance (high) Nylon

Cost:weight (low) Urea, phenolics, polystyrene,

polyethylene, polypropylene, PVC

Compressive strength Polyphthalamide, phenolic (glass),

epoxy, melamine, nylon, thermoplastic

polyester (glass), polyimide

Cost:volume (low) Polystyrene, polyethylene, urea,

phenolics, Polypropylene, PVC

Dielectric constant (high) Phenolic, PVC, fluorocarbon, melamine,

alkyd, nylon, polyphthalamide, epoxy

Dielectric strength (high) PVC, fluorocarbon, polypropylene,

polyphenylene, ether, phenolic, TP

polyester, nylon (glass), polyolefin,

polyethylene

Dissipation factor (high) PVC, fluorocarbon, phenolic, TP

polyester, nylon, epoxy, diallyl phthalate,

polyurethane

Distortion, Thermosetting laminates

resistance to under load (high)

Elastic modulus (high) Melamine, urea, phenolics

Elastic modulus (low) Polyethylene, polycarbonate,

fluorocarbons

Electrical resistivity (high) Polystyrene, fluorocarbons,

polypropylene

Elongation at break (high) Polyethylene, polypropylene, silicone,

ethylene vinylacetate

Elongation at break (low) Polyether sulfone, polycarbonate (glass),

nylon (glass), polypropylene (glass),

thermoplastic polyester, polyetherimide,

vinyl ester, polyetheretherketone, epoxy,

polyimide

Flexural modulus (stiffness) Polyphenylene sulfide, epoxy, phenolic

(glass), nylon (glass), polyimide, diallyl

phthalate, polyphthalamide,TP polyester

DAVE TECHNICAL SERVICES 10