Page 9 - C:\Users\Adik\Documents\Flip PDF Professional\Marketer PPT LR\

P. 9

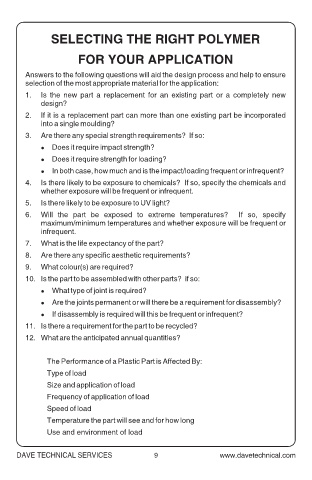

SELECTING THE RIGHT POLYMER

FOR YOUR APPLICATION

Answers to the following questions will aid the design process and help to ensure

selection of the most appropriate material for the application:

1. Is the new part a replacement for an existing part or a completely new

design?

2. If it is a replacement part can more than one existing part be incorporated

into a single moulding?

3. Are there any special strength requirements? If so:

lDoes it require impact strength?

l Does it require strength for loading?

lIn both case, how much and is the impact/loading frequent or infrequent?

4. Is there likely to be exposure to chemicals? If so, specify the chemicals and

whether exposure will be frequent or infrequent.

5. Is there likely to be exposure to UV light?

6. Will the part be exposed to extreme temperatures? If so, specify

maximum/minimum temperatures and whether exposure will be frequent or

infrequent.

7. What is the life expectancy of the part?

8. Are there any specific aesthetic requirements?

9. What colour(s) are required?

10. Is the part to be assembled with other parts? if so:

lWhat type of joint is required?

lAre the joints permanent or will there be a requirement for disassembly?

lIf disassembly is required will this be frequent or infrequent?

11. Is there a requirement for the part to be recycled?

12. What are the anticipated annual quantities?

The Performance of a Plastic Part is Affected By:

Type of load

Size and application of load

Frequency of application of load

Speed of load

Temperature the part will see and for how long

Use and environment of load

DAVE TECHNICAL SERVICES 9