Page 4 - C:\Users\Adik\Documents\Flip PDF Professional\Marketer PPT LR\

P. 4

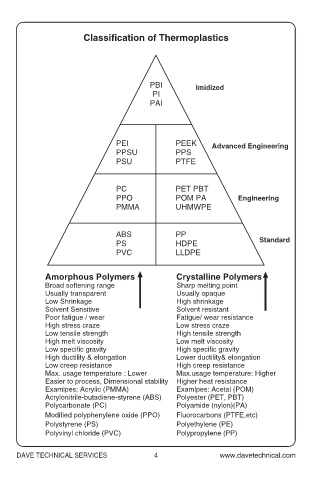

Classification of Thermoplastics

PBI

Imidized

PI

PAI

PEI PEEK Advanced Engineering

PPSU PPS

PSU PTFE

PC PET PBT

PPO POM PA Engineering

PMMA UHMWPE

ABS PP

PS HDPE Standard

PVC LLDPE

Amorphous Polymers Crystalline Polymers

Broad softening range Sharp melting point

Usually transparent Usually opaque

Low Shrinkage High shrinkage

Solvent Sensitive Solvent resistant

Poor fatigue / wear Fatigue/ wear resistance

High stress craze Low stress craze

Low tensile strength High tensile strength

High melt viscosity Low melt viscosity

Low specific gravity High specific gravity

High ductility & elongation Lower ductility& elongation

Low creep resistance High creep resistance

Max. usage temperature : Lower Max.usage temperature: Higher

Easier to process, Dimensional stability Higher heat resistance

Examlpes: Acrylic (PMMA) Examlpes: Acetal (POM)

Acrylonitrile-butadiene-styrene (ABS) Polyester (PET, PBT)

Polycarbonate (PC) Polyamide (nylon)(PA)

Modified polyphenylene oxide (PPO) Fluorocarbons (PTFE,etc)

Polystyrene (PS) Polyethylene (PE)

Polyvinyl chloride (PVC) Polypropylene (PP)

DAVE TECHNICAL SERVICES 4