Page 3 - C:\Users\Adik\Documents\Flip PDF Professional\Marketer PPT LR\

P. 3

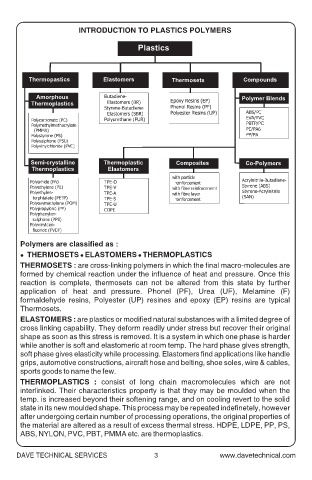

INTRODUCTION TO PLASTICS POLYMERS

Plastics

Thermopastics Elastomers Thermosets Compounds

Amorphous Polymer Blends

Thermoplastics

Semi-crystalline Thermoplastic Composites Co-Polymers

Thermoplastics Elastomers

Polymers are classified as :

l

l THERMOSETS ELASTOMERS THERMOPLASTICS

l

THERMOSETS : are cross-linking polymers in which the final macro-molecules are

formed by chemical reaction under the influence of heat and pressure. Once this

reaction is complete, thermosets can not be altered from this state by further

application of heat and pressure. Phonel (PF), Urea (UF), Melamine (F)

formaldehyde resins, Polyester (UP) resines and epoxy (EP) resins are typical

Thermosets.

ELASTOMERS : are plastics or modified natural substances with a limited degree of

cross linking capability. They deform readily under stress but recover their original

shape as soon as this stress is removed. It is a system in which one phase is harder

while another is soft and elastomeric at room temp. The hard phase gives strength,

soft phase gives elasticity while processing. Elastomers find applications like handle

grips, automotive constructions, aircraft hose and belting, shoe soles, wire & cables,

sports goods to name the few.

THERMOPLASTICS : consist of long chain macromolecules which are not

interlinked. Their characteristics property is that they may be moulded when the

temp. is increased beyond their softening range, and on cooling revert to the solid

state in its new moulded shape. This process may be repeated indefinetely, however

after undergoing certain number of processing operations, the original properties of

the material are altered as a result of excess thermal stress. HDPE, LDPE, PP, PS,

ABS, NYLON, PVC, PBT, PMMA etc. are thermoplastics.

DAVE TECHNICAL SERVICES 3