Page 163 - C:\Users\Adik\Documents\Flip PDF Professional\Marketer PPT LR\

P. 163

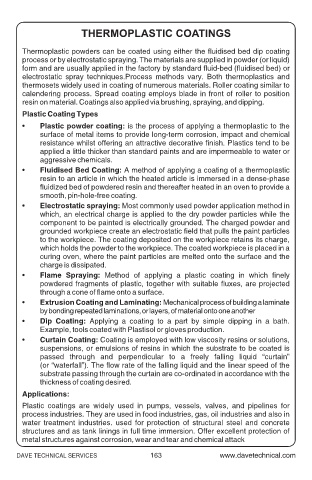

THERMOPLASTIC COATINGS

Thermoplastic powders can be coated using either the fluidised bed dip coating

process or by electrostatic spraying. The materials are supplied in powder (or liquid)

form and are usually applied in the factory by standard fluid-bed (fluidised bed) or

electrostatic spray techniques.Process methods vary. Both thermoplastics and

thermosets widely used in coating of numerous materials. Roller coating similar to

calendering process. Spread coating employs blade in front of roller to position

resin on material. Coatings also applied via brushing, spraying, and dipping.

Plastic Coating Types

• Plastic powder coating: is the process of applying a thermoplastic to the

surface of metal items to provide long-term corrosion, impact and chemical

resistance whilst offering an attractive decorative finish. Plastics tend to be

applied a little thicker than standard paints and are impermeable to water or

aggressive chemicals.

• Fluidised Bed Coating: A method of applying a coating of a thermoplastic

resin to an article in which the heated article is immersed in a dense-phase

fluidized bed of powdered resin and thereafter heated in an oven to provide a

smooth, pin-hole-free coating.

• Electrostatic spraying: Most commonly used powder application method in

which, an electrical charge is applied to the dry powder particles while the

component to be painted is electrically grounded. The charged powder and

grounded workpiece create an electrostatic field that pulls the paint particles

to the workpiece. The coating deposited on the workpiece retains its charge,

which holds the powder to the workpiece. The coated workpiece is placed in a

curing oven, where the paint particles are melted onto the surface and the

charge is dissipated.

• Flame Spraying: Method of applying a plastic coating in which finely

powdered fragments of plastic, together with suitable fluxes, are projected

through a cone of flame onto a surface.

• Extrusion Coating and Laminating: Mechanical process of building a laminate

by bonding repeated laminations, or layers, of material onto one another

• Dip Coating: Applying a coating to a part by simple dipping in a bath.

Example, tools coated with Plastisol or gloves production.

• Curtain Coating: Coating is employed with low viscosity resins or solutions,

suspensions, or emulsions of resins in which the substrate to be coated is

passed through and perpendicular to a freely falling liquid “curtain”

(or “waterfall”). The flow rate of the falling liquid and the linear speed of the

substrate passing through the curtain are co-ordinated in accordance with the

thickness of coating desired.

Applications:

Plastic coatings are widely used in pumps, vessels, valves, and pipelines for

process industries. They are used in food industries, gas, oil industries and also in

water treatment industries. used for protection of structural steel and concrete

structures and as tank linings in full time immersion. Offer excellent protection of

metal structures against corrosion, wear and tear and chemical attack

DAVE TECHNICAL SERVICES 163