Page 161 - C:\Users\Adik\Documents\Flip PDF Professional\Marketer PPT LR\

P. 161

15. Electrolytic Plating Process: Plating requires the plastic parts to be

electrically conductive. To achieve this conductivity, the plastic parts are subjected

to an electroless plating operation. Plastic parts are first submersed in a sulfuric

chromic acid bath which slightly etches the plastic surface, creating microscopic

pockmarks. The plastic parts are then placed in a activator bath, and an accelerator

bath making the parts chemically attractive to the metals suspended in the

electroless plating bath solution. These plating metals get deposited in the

pockmarks. It is the first phase in the electrolytic plating process which provides a

dull metallic finish and makes the parts electrically conductive. Electrolytic plating

creates bright chrome surfaces.

16. Dyeing, where dye molecules penetrate below the surface.

17. Mechanical surface changes, such as polishing, grinding and embossing &

surface textures.

18. Sublimation Printing: In sublimation (diffusion) printing, color in dry dye

crystals is transferred from a release film to a plastic substrate under heat and

pressure. The dye crystals vaporize and the vapor penetrates the plastic part,

yielding a durable, wear-resistant decoration. This process is cost competitive with

other processes, such as two-stage injection molding or silk screening. It is,

however, limited to polyesters and polyester-based alloys by currently available

dyes intended for textile applications. New dyes are under development for

applications with other than polyester-based thermoplastics.

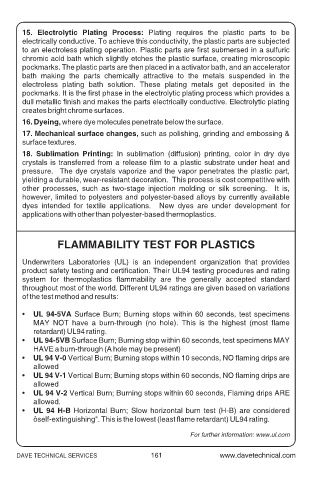

FLAMMABILITY TEST FOR PLASTICS

Underwriters Laboratories (UL) is an independent organization that provides

product safety testing and certification. Their UL94 testing procedures and rating

system for thermoplastics flammability are the generally accepted standard

throughout most of the world. Different UL94 ratings are given based on variations

of the test method and results:

• UL 94-5VA Surface Burn; Burning stops within 60 seconds, test specimens

MAY NOT have a burn-through (no hole). This is the highest (most flame

retardant) UL94 rating.

• UL 94-5VB Surface Burn; Burning stop within 60 seconds, test specimens MAY

HAVE a burn-through (A hole may be present)

• UL 94 V-0 Vertical Burn; Burning stops within 10 seconds, NO flaming drips are

allowed

• UL 94 V-1 Vertical Burn; Burning stops within 60 seconds, NO flaming drips are

allowed

• UL 94 V-2 Vertical Burn; Burning stops within 60 seconds, Flaming drips ARE

allowed.

• UL 94 H-B Horizontal Burn; Slow horizontal burn test (H-B) are considered

ôself-extinguishing". This is the lowest (least flame retardant) UL94 rating.

For further information: www.ul.com

DAVE TECHNICAL SERVICES 161