Page 157 - C:\Users\Adik\Documents\Flip PDF Professional\Marketer PPT LR\

P. 157

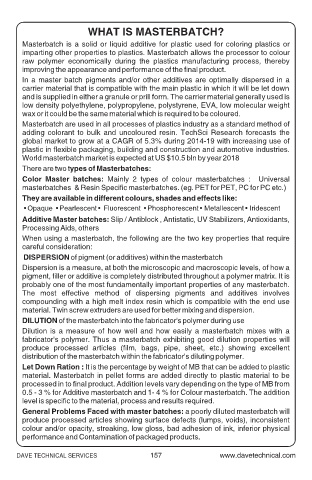

WHAT IS MASTERBATCH?

Masterbatch is a solid or liquid additive for plastic used for coloring plastics or

imparting other properties to plastics. Masterbatch allows the processor to colour

raw polymer economically during the plastics manufacturing process, thereby

improving the appearance and performance of the final product.

In a master batch pigments and/or other additives are optimally dispersed in a

carrier material that is compatible with the main plastic in which it will be let down

and is supplied in either a granule or prill form. The carrier material generally used is

low density polyethylene, polypropylene, polystyrene, EVA, low molecular weight

wax or it could be the same material which is required to be coloured.

Masterbatch are used in all processes of plastics industry as a standard method of

adding colorant to bulk and uncoloured resin. TechSci Research forecasts the

global market to grow at a CAGR of 5.3% during 2014-19 with increasing use of

plastic in flexible packaging, building and construction and automotive industries.

World masterbatch market is expected at US $10.5 bln by year 2018

There are two types of Masterbatches:

Color Master batches: Mainly 2 types of colour masterbatches : Universal

masterbatches & Resin Specific masterbatches. (eg. PET for PET, PC for PC etc.)

They are available in different colours, shades and effects like:

?• Opaque • Pearlescent • Fluorescent • Phosphorescent • Metallescent • Iridescent

Additive Master batches: Slip / Antiblock , Antistatic, UV Stabilizers, Antioxidants,

Processing Aids, others

When using a masterbatch, the following are the two key properties that require

careful consideration:

DISPERSION of pigment (or additives) within the masterbatch

Dispersion is a measure, at both the microscopic and macroscopic levels, of how a

pigment, filler or additive is completely distributed throughout a polymer matrix. It is

probably one of the most fundamentally important properties of any masterbatch.

The most effective method of dispersing pigments and additives involves

compounding with a high melt index resin which is compatible with the end use

material. Twin screw extruders are used for better mixing and dispersion.

DILUTION of the masterbatch into the fabricator's polymer during use

Dilution is a measure of how well and how easily a masterbatch mixes with a

fabricator's polymer. Thus a masterbatch exhibiting good dilution properties will

produce processed articles (film, bags, pipe, sheet, etc.) showing excellent

distribution of the masterbatch within the fabricator's diluting polymer.

Let Down Ration : It is the percentage by weight of MB that can be added to plastic

material. Masterbatch in pellet forms are added directly to plastic material to be

processed in to final product. Addition levels vary depending on the type of MB from

0.5 - 3 % for Additive masterbatch and 1- 4 % for Colour masterbatch. The addition

level is specific to the material, process and results required.

General Problems Faced with master batches: a poorly diluted masterbatch will

produce processed articles showing surface defects (lumps, voids), inconsistent

colour and/or opacity, streaking, low gloss, bad adhesion of ink, inferior physical

performance and Contamination of packaged products.

DAVE TECHNICAL SERVICES 157