Page 156 - C:\Users\Adik\Documents\Flip PDF Professional\Marketer PPT LR\

P. 156

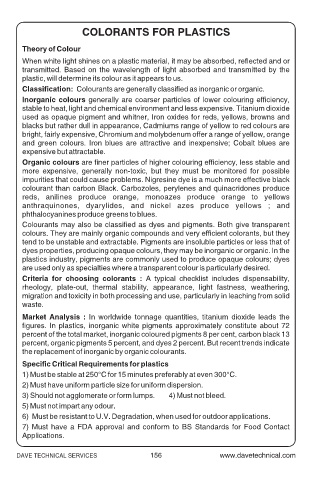

COLORANTS FOR PLASTICS

Theory of Colour

When white light shines on a plastic material, it may be absorbed, reflected and or

transmitted. Based on the wavelength of light absorbed and transmitted by the

plastic, will determine its colour as it appears to us.

Classification: Colourants are generally classified as inorganic or organic.

Inorganic colours generally are coarser particles of lower colouring efficiency,

stable to heat, light and chemical environment and less expensive. Titanium dioxide

used as opaque pigment and whitner, Iron oxides for reds, yellows, browns and

blacks but rather dull in appearance, Cadmiums range of yellow to red colours are

bright, fairly expensive, Chromium and molybdenum offer a range of yellow, orange

and green colours. Iron blues are attractive and inexpensive; Cobalt blues are

expensive but attractable.

Organic colours are finer particles of higher colouring efficiency, less stable and

more expensive, generally non-toxic, but they must be monitored for possible

impurities that could cause problems. Nigresine dye is a much more effective black

colourant than carbon Black. Carbozoles, perylenes and quinacridones produce

reds, anilines produce orange, monoazes produce orange to yellows

anthraquinones, dyarylides, and nickel azes produce yellows ; and

phthalocyanines produce greens to blues.

Colourants may also be classified as dyes and pigments. Both give transparent

colours. They are mainly organic compounds and very efficient colorants, but they

tend to be unstable and extractable. Pigments are insoluble particles or less that of

dyes properties, producing opaque colours, they may be inorganic or organic. In the

plastics industry, pigments are commonly used to produce opaque colours; dyes

are used only as specialties where a transparent colour is particularly desired.

Criteria for choosing colorants : A typical checklist includes dispensability,

rheology, plate-out, thermal stability, appearance, light fastness, weathering,

migration and toxicity in both processing and use, particularly in leaching from solid

waste.

Market Analysis : In worldwide tonnage quantities, titanium dioxide leads the

figures. In plastics, inorganic white pigments approximately constitute about 72

percent of the total market, inorganic coloured pigments 8 per cent, carbon black 13

percent, organic pigments 5 percent, and dyes 2 percent. But recent trends indicate

the replacement of inorganic by organic colourants.

Specific Critical Requirements for plastics

1) Must be stable at 250°C for 15 minutes preferably at even 300°C.

2) Must have uniform particle size for uniform dispersion.

3) Should not agglomerate or form lumps. 4) Must not bleed.

5) Must not impart any odour.

6) Must be resistant to U.V. Degradation, when used for outdoor applications.

7) Must have a FDA approval and conform to BS Standards for Food Contact

Applications.

DAVE TECHNICAL SERVICES 156