Page 211 - C:\Users\Adik\Documents\Flip PDF Professional\Marketer PPT LR\

P. 211

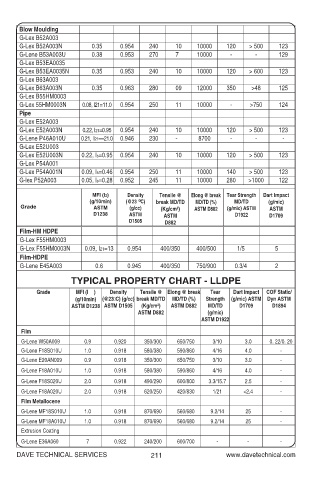

Blow Moulding

G-Lex B52A003

G-Lex B52A003N 0.35 0.954 240 10 10000 120 > 500 123

G-Lene B53A003U 0.38 0.953 270 7 10000 - - 129

G-Lex B53EA0035

G-Lex B53EA0035N 0.35 0.953 240 10 10000 120 > 600 123

G-Lex B63A003

G-Lex B63A003N 0.35 0.963 280 09 12000 350 >48 125

G-Lex B55HM0003

G-Lex 55HM0003N 0.08, I21=11.0 0.954 250 11 10000 - >750 124

Pipe

G-Lex E52A003

G-Lex E52A003N 0.22, I21=0.95 0.954 240 10 10000 120 > 500 123

G-Lene P46A010U 0.21, I21==21.0 0.946 230 - 8700 - - -

G-Lex E52U003

G-Lex E52U003N 0.22, Is=0.95 0.954 240 10 10000 120 > 500 123

G-Lex P54A001

G-Lex P54A001N 0.09, Is=0.46 0.954 250 11 10000 140 > 500 123

G-lex P52A003 0.05, Is=0.28 0.952 245 11 10000 280 >1000 122

MFI (I2) Density Tensile @ Elong @ break Tear Strength Dart Impact

o

(g/10min) (@23 C) break MD/TD MD/TD (%) MD/TD (g/mic)

Grade ASTM (g/cc) (Kg/cm²) ASTM D882 (g/mic) ASTM ASTM

D1238 ASTM ASTM D1922 D1709

D1505 D882

Film-HM HDPE

G-Lex F55HM0003

G-Lex F55HM0003N 0.09, I21=13 0.954 400/350 400/500 1/5 5

Film-HDPE

G-Lene E45A003 0.6 0.945 400/350 750/900 0.3/4 2

TYPICAL PROPERTY CHART - LLDPE

Grade MFI (I͐) Density Tensile @ Elong @ break Tear Dart Impact COF Static/

(g/10min) (@23°C) (g/cc) break MD/TD MD/TD (%) Strength (g/mic) ASTM Dyn ASTM

ASTM D1238 ASTM D1505 (Kg/cm²) ASTM D882 MD/TD D1709 D1894

ASTM D882 (g/mic)

ASTM D1922

Film

G-Lene W50A009 0.9 0.920 350/300 650/750 3/10 3.0 0. 22/0. 20

G-Lene F18S010U 1.0 0.918 580/380 590/860 4/16 4.0 -

G-Lene E20AN009 0.9 0.918 350/300 650/750 3/10 3.0 -

G-Lene F18A010U 1.0 0.918 580/380 590/860 4/16 4.0 -

G-Lene F18S020U 2.0 0.918 490/290 600/800 3.3/15.7 2.5 -

G-Lene F18A020U 2.0 0.918 620/250 420/830 1/21 <2.4 -

Film Metallocene

G-Lene MF18S010U 1.0 0.918 870/690 560/680 9.2/14 25 -

G-Lene MF18A010U 1.0 0.918 870/690 560/680 9.2/14 25 -

Extrusion Coating

G-Lene E36A060 7 0.922 240/200 600/700 - - -

DAVE TECHNICAL SERVICES 211 www.davetechnical.com