Page 41 - Hot Runner & Control Systems 2020

P. 41

Hot One Nozzles 29 39

Housing, Nozzle Plate and

Gate Machining Dimensions Detail

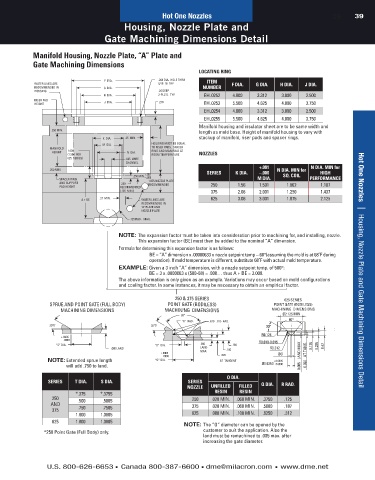

Manifold Housing, Nozzle Plate, “A” Plate and

Gate Machining Dimensions Ø4.000 LOCATING RING BORE Ø2.756 0.000 HEAD BORE

+0.001

LOCATING RING

Ø2.125 HEATER BORE

F DIA. .261 DIA. HOLE THRU ITEM

WATER LINES ARE 5/16–18 TAP F DIA. G DIA. H DIA. J DIA. Ø8.00 DWL

RECOMMENDED IN G DIA. NUMBER BUSHING HEATER (OPTIONAL FOR

HOUSING .34 DEEP CABLE EXIT ANTI-ROTATION)

H DIA. 2-PLC'S. TYP. EHL0252 4.000 3.312 3.000 2.500

RISER PAD J DIA. .219 0.75

HEIGHT EHL0253 5.500 4.625 4.000 3.750 1.174

EHL0254 4.000 3.312 3.000 2.500

EHL0255 5.500 4.625 4.000 3.750 (4) 5/16-18 UNC

Manifold housing and insulator sheet are to be same width and

.250 MIN. length as mold base. Height of manifold housing to vary with 1.174

3.50

K DIA. .25 MIN. stackup of manifold, riser pads and spacer rings. 1.378

M DIA. HOUSING MUST BE EQUAL Ø8 X18LG DWL

MANIFOLD TO RISER PADS, SPACER (OPTIONAL FOR

HEIGHT 1.000 N DIA. RING AND MANIFOLD AT NOZZLES NOTE: MATCH MACHINE ANTI-ROTATION)

(1.500 FOR ROOM TEMPERATURE NOZZLE TIP ORIFICE R 0.750

625 SERIES) .625 WIRE 6 INSULATION SHEET

CHANNEL 4 Ø0.625 (OPTIONAL)

+.001 N DIA. MIN for

5

.250 MIN. N DIA. MIN for

+.001 SERIES K DIA. –.000 HIGH 1.743

.250 MIN. –.000 SQ. COIL

SPACER RING 1.875 NOZZLE PLATE M DIA. PERFORMANCE

AND SUPPORT .250 RECOMMENDED 250 1.56 1.501 1.062 1.187

PAD HEIGHT RECOMMENDED

2

(.125 MIN.) 375 2.06 2.001 1.250 1.437

A + BE .31 MIN. WATER LINES ARE 625 3.06 3.001 1.875 R0.030 2.125

RECOMMENDED IN

"A" PLATE AND MIN. WIRE CHANNEL 0.375 2.125 0.06 X 45˚ 0.06 X 45˚ 0.06 X 45˚ 0.633 Min. - 1.283 Max.

NOZZLE PLATE MIN. 0.469 -0.001 HEAD C’BORE

.125 RAD. MAX. 3 0.000

1 A + BE

NOTE: The expansion factor must be taken into consideration prior to machining for, and installing, nozzle.

WATER LINES

This expansion factor (BE) must then be added to the nominal “A” dimension. 0.31 MIN. 1"-16 UN

TORQUE TO 30 FT/LBS

Formula for determining this expansion factor is as follows:

BE = “A” dimension x .00000633 x nozzle setpoint temp – 68°(assuming the mold is at 68˚F during

operation). If mold temperature is different, substitute 68˚F with actual mold temperature.

EXAMPLE: Given a 3 inch “A” dimension, with a nozzle setpoint temp. of 500°:

BE = 3 x .0000063 x (500-68) = .008… thus A + BE = 3.008. Custom Hot Runner Systems | New Products

The above information is only given as an example. Variations may occur based on mold configurations

and cooling factor. In some instances, it may be necessary to obtain an empirical factor.

250 & 375 SERIES 625 SERIES

GATE-MATE 4 SPRUE AND POINT GATE (FULL BODY) POINT GATE (BODILESS) POINT GATE (BODILESS)

MACHINING DIMENSIONS MACHINING DIMENSIONS MACHINING DIMENSIONS MACHINING DIMENSIONS

+.0005 80° Ø2.125 MIN Ø2.125 MIN Ø2.125 MIN Ø2.125 MIN

–.0000 “R” RAD. .010 –.015 RAD. 80°

30°0' .7500 DIA. 30°0' 30°0' 30° 30°

30° 30°

90° R0.125

.375 RAD. 80° .770 +.0005 +.0005 CUSTOMER +.0005 25° MAX.

–.0000

“S” DIA. “0” DIA. .005 .180 R0.010-0.015 0.125 0.235 ØS -.0000 MIN. RADIUS TO ØS -.0000 0.08 MIN. +.0005 0.08 MIN.

-.0000

.080 LAND LAND R0.312 0.47 SUIT ØS

.187 SPH. RAD. .030 +.0005 MAX. .100 AT TANG.

“0' DIA. .005 LAND (MAX. ) –.0000 .020 ØO 0.005 LAND MAX 0.08

NOTE: Extended sprue length “Q” DIA. AT TANGENT +0.0005

will add .750 to land. Ø0.6250 0.0000 0.020

O DIA.

SERIES T DIA. S DIA. SERIES

NOZZLE UNFILLED FILLED Q DIA. R RAD.

Hot One Nozzles | Housing, Nozzle Plate and Gate Machining Dimensions Detail

*.375 *.3755 RESIN RESIN

250 .500 .5005 250 .028 MIN. .060 MIN. .3750 .125

AND 375 .028 MIN. .060 MIN. .5000 .187

375 .750 .7505

1.000 1.0005 625 .080 MIN. .100 MIN. .6250 .312

625 1.000 1.0005

NOTE: The “O” diameter can be opened by the

*250 Point Gate (Full Body) only. customer to suit the application. Also the

land must be remachined to .005 max. after

increasing the gate diameter.

U.S. 800-626-6653 n Canada 800-387-6600 n dme@milacron.com n www.dme.net