Page 24 - March 2020 - WT Site

P. 24

Fig-2 (a) Disc diffuser (b) Tube diffusers

b. Jet Aeration System: To provide the oxygen source for the the decanting rate is not controlled. Generally used in small

biological reaction, a jet aeration manifold with multiple jet installations. Mechanical problems related to valve and actuators

nozzle assemblies is connected to a pump and a blower. Each require regular maintenance. This is of low cost. These are used

jet has a primary mixing nozzle and an outer secondary nozzle. in small installations. It is represented in Fig-3 [8].

Jet aeration provides high oxygen transfer and complete mixing

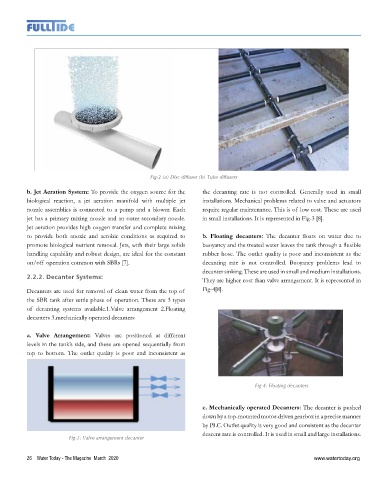

to provide both anoxic and aerobic conditions as required to b. Floating decanters: The decanter floats on water due to

promote biological nutrient removal. Jets, with their large solids buoyancy and the treated water leaves the tank through a flexible

handling capability and robust design, are ideal for the constant rubber hose. The outlet quality is poor and inconsistent as the

on/off operation common with SBRs [7]. decanting rate is not controlled. Buoyancy problems lead to

decanter sinking. These are used in small and medium installations.

2.2.2. Decanter Systems: They are higher cost than valve arrangement. It is represented in

Decanters are used for removal of clean water from the top of Fig-4[8].

the SBR tank after settle phase of operation. There are 3 types

of decanting systems available.1.Valve arrangement 2.Floating

decanters 3.mechanically operated decanters

a. Valve Arrangement: Valves are positioned at different

levels in the tank’s side, and these are opened sequentially from

top to bottom. The outlet quality is poor and inconsistent as

Fig-4: Floating decanters

c. Mechanically operated Decanters: The decanter is pushed

down by a top-mounted motor-driven gearbox in a precise manner

by PLC. Outlet quality is very good and consistent as the decanter

descent rate is controlled. It is used in small and large installations.

Fig-3: Valve arrangement decanter

26 Water Today - The Magazine March 2020