Page 11 - Parker - Hydraulic and Lube Filtration Products

P. 11

12AT/50AT Series

Spin-On Filters

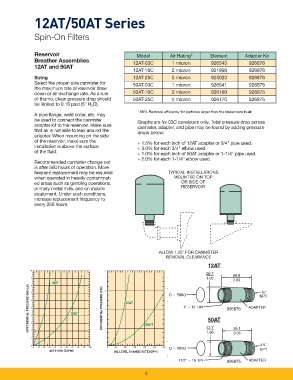

Reservoir Model Air Rating* Element Adapter Kit

Breather Assemblies

12AT-03C 1 micron 926543 926876

12AT and 50AT

12AT-10C 2 micron 921999 926876

Sizing 12AT-25C 5 micron 925023 926876

Select the proper size cannister for 50AT-03C 1 micron 926541 926875

the maximum rate of reservoir draw

down or air exchange rate. As a rule 50AT-10C 2 micron 926169 926875

of thumb, clean pressure drop should 50AT-25C 5 micron 926170 926875

be limited to 0.18 psid (5" H O).

2

* 99% Removal effi ciency for particles larger than the stated size in air.

A pipe fl ange, weld collar, etc. may

be used to connect the cannister Graphs are for 03C cannisters only. Total pressure drop across

adapter kit to the reservoir. Make sure cannister, adapter, and pipe may be found by adding pressure

that air is not able to leak around the drops below:

adapter. When mounting on the side

of the reservoir, make sure the + 1.5% for each inch of 12AT adapter or 3/4" pipe used.

installation is above the surface + 3.0% for each 3/4" elbow used.

of the fl uid.

+ 1.0% for each inch of 50AT adapter or 1-1/4" pipe used.

+ 2.0% for each 1-1/4" elbow used.

Recommended cannister change out

is after 500 hours of operation. More

frequent replacement may be required TYPICAL INSTALLATIONS

when operated in heavily contaminat- MOUNTED ON TOP

ed areas such as grinding operations, OR SIDE OF

primary metal mills, and on mobile RESERVOIR

equipment. Under such conditions,

increase replacement frequency to

every 250 hours.

ALLOW 1.25" FOR CANNISTER

REMOVAL CLEARANCE

10 10 .4

9 9

12AT .3

DIFFERENTIAL PRESSURE (IN H 2 O) 6 6 5 5 4 4 3 3 50AT DIFFERENTIAL PRESSURE (PSI) .2 12AT 926876

8 8

7 7

1 1 2 2 .1 50AT

0 0

1

0 0 100 1 200 2 300 3 400 4 5 500 600 6 7 700 800 8 900 9 10000 0 100 200 300 400 500 600

AIR FLOW (SCFM) OIL LEVEL CHANGE RATE (GPM)

926875

6