Page 305 - Schroeder - Hydraulic And Lube Filtration

P. 305

Spin-On Filter MAF1

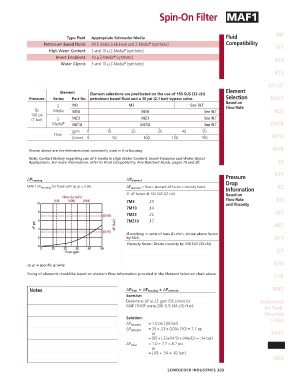

Type Fluid Appropriate Schroeder Media Fluid IRF

Petroleum Based Fluids All E media (cellulose) and Z-Media (synthetic) Compatibility TF1

®

High Water Content 3 and 10 µ Z-Media (synthetic)

®

Invert Emulsions 10 µ Z-Media (synthetic) KF3

®

®

Water Glycols 3 and 10 µ Z-Media (synthetic)

KL3

LF1–2"

Element Element selections are predicated on the use of 150 SUS (32 cSt) Element

Pressure Series Part No. petroleum based fluid and a 30 psi (2.1 bar) bypass valve. Selection MLF1

Based on

E M3 M3 See RLT Flow Rate

To Media M10 M10 See RLT RLD

100 psi

(7 bar) Z- MZ3 MZ3 See RLT

Media ® MZ10 MZ10 See RLT GRTB

gpm 0 10 20 30 40 50

Flow

(L/min) 0 50 100 150 190 MTA

Shown above are the elements most commonly used in this housing. MTB

Note: Contact factory regarding use of E media in High Water Content, Invert Emulsion and Water Glycol

Applications. For more information, refer to Fluid Compatibility: Fire Resistant Fluids, pages 19 and 20. ZT

Pressure KFT

∆P housing ∆P element

Drop

MAF1 ∆P housing for fluids with sp gr = 0.86: ∆P element = flow x element ∆P factor x viscosity factor Information RT

El. ∆P factors @ 150 SUS (32 cSt): Based on

7M3 .23 Flow Rate RTI

and Viscosity

7M10 .14

7MZ3 .22 LRT

7MZ10 .17

ART

If working in units of bars & L/min, divide above factor

by 54.9. BFT

Viscosity factor: Divide viscosity by 150 SUS (32 cSt).

QT

sp gr = specific gravity KTK

Sizing of elements should be based on element flow information provided in the Element Selection chart above.

LTK

Notes ∆P filter = ∆P housing + ∆P element MRT

Exercise:

Determine ∆P at 25 gpm (95 L/min) for Accessories

MAF17M3P using 200 SUS (44 cSt) fluid. for Tank-

Mounted

Solution: Filters

∆P housing = 1.0 psi [.08 bar]

∆P element = 25 x .23 x (200÷150) = 7.7 psi

or PAF1

= [95 x (.23÷54.9) x (44÷32) = .54 bar]

∆P total = 1.0 + 7.7 = 8.7 psi MAF1

or

= [.08 + .54 = .62 bar]

MF2

SCHROEDER INDUSTRIES 303