Page 90 - Parker Parflex Thermoplastic & Fluoropolymer Products Hose, Tubing, & Fittings 2017 - Cat 4460

P. 90

Hose

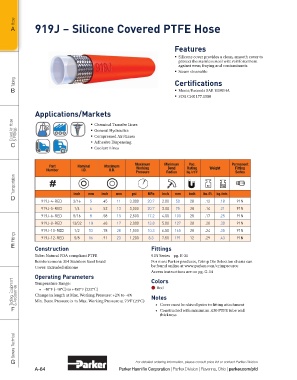

A 919J – Silicone Covered PTFE Hose

Features

Silicone cover provides a clean, smooth cover to

protect the stainless steel wire reinforcement

against wear, fraying and contaminants

Steam cleanable

Tubing Certifications

B Meets/Exceeds SAE 100R14A

FDA CFR 177.1550

Applications/Markets

Coiled Air Hose & Fittings Chemical Transfer Lines

General Hydraulics

Compressed Air/Gases

C Adhesive Dispensing

Coolant Lines

Part Nominal Maximum Maximum Minimum Vac. Permanent

Working

Rating

Bend

Number I.D. O.D. Pressure Radius Hg./73˚F Weight Fitting

Series

Transportation lbs

D inch mm inch mm psi MPa inch mm inch lbs./ft. kg./mtr.

919J-4-RED 3/16 5 .45 11 3,000 20.7 2.00 50 28 .12 .18 91N

919J-5-RED 1/4 6 .52 13 3,000 20.7 3.00 75 28 .14 .21 91N

919J-6-RED 5/16 8 .58 15 2,500 17.2 4.00 100 28 .17 .25 91N

919J-8-RED 13/32 10 .68 17 2,000 13.8 5.00 127 28 .20 .30 91N

919J-10-RED 1/2 13 .78 20 1,500 10.3 6.50 165 28 .24 .35 91N

Fittings 919J-12-RED 5/8 16 .91 23 1,200 8.3 7.50 191 12 .29 .43 91N

E Construction Fittings

Tube: Natural FDA compliant PTFE 91N Series – pg. E-31

Reinforcement: 304 Stainless Steel braid For most Parker products, Crimp Die Selection charts can

Cover: Extruded silicone be found online at www.parker.com/crimpsource

Access instructions are on pg. G-14

Operating Parameters Colors

Tooling, Equipment & Accessories Change in length at Max. Working Pressure: +2% to -4% Notes

Temperature Range:

Red

• -40°F (-40°C) to +450°F (232°C)

F Min. Burst Pressure is 4x Max. Working Pressure at 73°F (23°C) • Cover must be skived prior to fitting attachment

• Constructed with minimum .030 PTFE tube wall

thickness

General Technical

G For detailed ordering information, please consult price list or contact Parflex Division.

A-64 Parker Hannifin Corporation | Parflex Division | Ravenna, Ohio | parker.com/pfd