Page 9 - Parker - General Technical

P. 9

4300 Catalog General Technical

Temperature T Return

To

Examples: Index

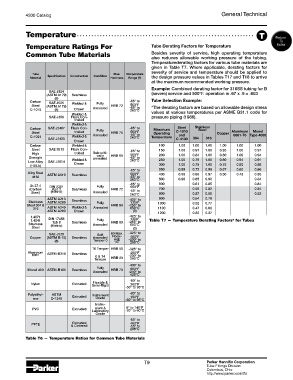

Temperature Ratings For Tube Derating Factors for Temperature

Common Tube Materials Besides severity of service, high operating temperature

also reduces allowable working pressure of the tubing.

Temperaturederating factors for various tube materials are

given in Table T7. Where applicable, derating factors for

severity of service and temperature should be applied to

Tube Max. Temperature

Material Specification Construction Condition Hardness Range (7) the design pressure values in Tables T17 and T18 to arrive

at the maximum recommended working pressure.

Example: Combined derating factor for 316SS tubing for B

SAE J524 (severe) service and 500°F. operation is .67 x .9 = .603

(ASTM A179) Seamless

(8)

Carbon SAE J525 Welded & Fully -65° to Tube Selection Example:

Steel (ASTM A178) HRB 72 500°F *The derating factors are based on allowable design stress

C-1010 (8) Drawn Annealed -55° to values at various temperatures per ASME B31.1 code for

260°C

Welded &

SAE J356 Flash Con- pressure piping (1986).

trolled

Welded &

Carbon SAE J2467 Flash Con- Fully -65° to Maximum Steel Stainless

Steel

Steel trolled HRB 75 500°F Operating C-1010 Copper Aluminum Monel

C-1021 Welded & Annealed -55° to Temperature and 6061-T6 Type 4000

260°C

SAE J2435 C-4130 304 316

Drawn

Carbon Welded & 100 1.00 1.00 1.00 1.00 1.00 1.00

Steel SAE 2613 Flash Con- -65° to 150 1.00 0.91 1.00 0.85 1.00 0.97

High trolled Sub-criti- 500°F 200 1.00 0.84 1.00 0.80 1.00 0.94

cally

Strength annealed HRB 90 -55° to

Low Alloy SAE J2614 Welded & 260°C 250 1.00 0.79 1.00 0.80 0.94 0.91

Drawn

(HSLA) 300 1.00 0.75 1.00 0.78 0.80 0.88

-65° to 350 0.99 0.72 0.99 0.67 0.60 0.86

Alloy Steel ASTM A519 Seamless 500°F 400 0.98 0.69 0.97 0.50 0.43 0.85

4130 -55° to

260°C 500 0.96 0.65 0.90 0.84

-65° to 600 0.61 0.85 0.84

St 37.4 DIN 2391 Fully 500°F

(Carbon Part 2 Seamless HRB 72 -55° to 700 0.59 0.82 0.84

Steel) (Metric) Annealed 800 0.57 0.80 0.83

Example: ASTM A213 260°C 900 0.54 0.78

Stainless ASTM A269 Seamless Fully -425° to 1000 0.52 0.77

1200°

Steel 304 & HRB 90 -255° to

316 ASTM A249 Welded & Annealed 650°C 1100 0.47 0.62

ASTM A269 Drawn (3) 1200 0.32 0.37

1.4571 DIN 17458 -425° to

1200°

1.4541 Fully -255° to Table T7 — Temperature Derating Factors* for Tubes

Stainless Tab 8 Seamless Annealed HRB 90 650°C

Steel (Metric) (3)

SAE J528 Soft 60 Max. -325° to

Copper (ASTM B-75) Seamless Annealed Rock- 400°F

well

(8) Temper 0 15T -200° to

205°C

T6 Temper HRB 56 -325° to

Aluminum ASTM-B210 Seamless 400°F

6061 0 & T4 -200° to

Temper HRB 30 205°C

-400° to

Fully

Monel 400 ASTM-B165 Seamless HRB 70 800°F

Annealed -240° to

425°C

Flexible &

Nylon Extruded Semi-Rigid -60° to

200°F

-50° to 95°C

Polyethyl- ASTM Extruded Instrument -80° to

150°F

ene D-1248 Grade -60° to 65°C

Instru-

PVC Extruded ment & 0° to 140°F

Laboratory -20° to 60°C

Grade

-65° to

Extruded

400°F

PFTE & Cintered -55° to

205°C

Table T6 — Temperature Ratios for Common Tube Materials

T9 Parker Hannifin Corporation

Tube Fittings Division

Columbus, Ohio

http://www.parker.com/tfd