Page 8 - Apollo - Flanged Series Y-Strainers

P. 8

FLANGED SERIES Y-STRAINERS

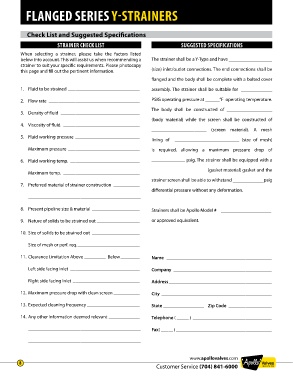

Check List and Suggested Specifications

STRAINER CHECK LIST SUGGESTED SPECIFICATIONS

When selecting a strainer, please take the factors listed

below into account. This will assist us when recommending a The strainer shall be a Y-Type and have __________________

strainer to suit your specific requirements. Please photocopy

this page and fill out the pertinent information. (size) inlet/outlet connections. The end connections shall be

flanged and the body shall be complete with a bolted cover

1. Fluid to be strained ______________________________ assembly. The strainer shall be suitable for _____________

2. Flow rate ______________________________________ PSIG operating pressure at ______°F operating temperature.

The body shall be constructed of ___________________

3. Density of fluid _________________________________

(body material) while the screen shall be constructed of

4. Viscosity of fluid ________________________________

_______________________ (screen material). A mesh

5. Fluid working pressure ___________________________

lining of ___________________________ (size of mesh)

Maximum pressure ______________________________ is required, allowing a maximum pressure drop of

6. Fluid working temp. _____________________________ ______________ psig. The strainer shall be equipped with a

_______________________ (gasket material) gasket and the

Maximum temp. ________________________________

strainer screen shall be able to withstand _____________psig

7. Preferred material of strainer construction ___________

differential pressure without any deformation.

_______________________________________________

8. Present pipeline size & material ____________________ Strainers shall be Apollo Model # _____________________

9. Nature of solids to be strained out __________________ or approved equivalent.

10. Size of solids to be strained out ____________________

Size of mesh or perf. req. __________________________

11. Clearance Limitation Above _________ Below ________ Name ____________________________________________

Left side facing inlet _____________________________ Company _________________________________________

Right side facing inlet ____________________________ Address ___________________________________________

12. Maximum pressure drop with clean screen ___________ City ______________________________________________

13. Expected cleaning frequency ______________________ State _________________ Zip Code __________________

14. Any other information deemed relevant _____________ Telephone ( _____ ) _________________________________

_______________________________________________ Fax( _____ ) ________________________________________

_______________________________________________

www.apollovalves.com

8

Customer Service (704) 841-6000