Page 27 - Parker Catalog 4400 - Hose, Fittings and Equipment

P. 27

Parker Fittings Metric fittings Custom fittings for and BSP in a wide range of sizes.

Material options include steel,

The products of choice for custom and standard Parker’s metric fittings are available short-run or special stainless steel and brass. All of

applications

in a full range of DIN, BSP, BSPP,

applications French GAZ, and JIS configurations Custom tube and hose fittings our products are manufactured to

world-class standards.

are available from Parker.

to meet worldwide applications.

Parker’s metric fittings are available Configurations include NPTF,

in a wide range of sizes to meet JIC, SAE, GAZ, ISO, DIN, JIS,

your requirements.

Field attachable Hose Hint

fittings How tight is tight enough? Differences in platings and other variables

can affect the amount of torque required to ensure a proper connection.

Parker field attachable fittings Always refer to this catalog or go to www.parkerhose.com for proper

enable you to make hose assembly procedures.

assemblies right at the job site

without special tools or machines.

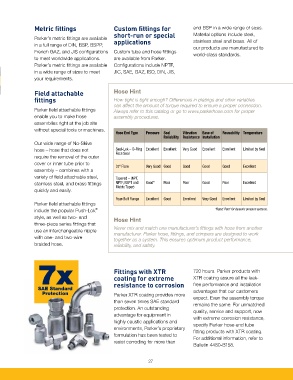

Hose End Type Pressure Seal Vibration Ease of Reusability Temperature

Reliability Resistance Installation

Our wide range of No-Skive

hose – hose that does not Seal-Lok – O-Ring Excellent Excellent Very Good Excellent Excellent Limited by Seal

require the removal of the outer Face Seal

cover or inner tube prior to 37º Flare Very Good Good Good Good Good Excellent

assembly – combines with a

variety of field attachable steel, Tapered – (NPT,

stainless steel, and brass fittings NPTF, BSPT and Good* Poor Poor Good Poor Excellent

Metric Taper)

quickly and easily.

Four-Bolt Flange Excellent Good Excellent Very Good Excellent Limited by Seal

Parker field attachable fittings

®

include the popular Push-Lok *Rated ‘Poor’ for dynamic pressure systems.

style, as well as two- and Hose Hint

three-piece series fittings that

use an interchangeable nipple Never mix and match one manufacturer’s fittings with hose from another

manufacturer. Parker hose, fittings, and crimpers are designed to work

with one- and two-wire together as a system. This ensures optimum product performance,

braided hose. reliability, and safety.

7x Fittings with XTR 720 hours. Parker products with

coating for extreme

XTR coating assure all the leak-

SAE Standard resistance to corrosion free performance and installation

advantages that our customers

Protection Parker XTR coating provides more

than seven times SAE standard expect. Even the assembly torque

remains the same. For unmatched

protection. An outstanding quality, service and support, now

advantage for equipment in with extreme corrosion resistance,

highly caustic applications and specify Parker hose and tube

environments, Parker’s proprietary fitting products with XTR coating.

formulation has been tested to For additional information, refer to

resist corroding for more than

Bulletin 4480-B158.

27