Page 4 - Parker Catalog 4400 - Hose, Fittings and Equipment

P. 4

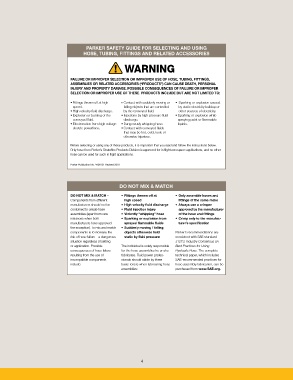

PARKER SAFETY GUIDE FOR SELECTING AND USING

HOSE, TUBING, FITTINGS AND RELATED ACCESSORIES

WARNING

FAILURE OR IMPROPER SELECTION OR IMPROPER USE OF HOSE, TUBING, FITTINGS,

ASSEMBLIES OR RELATED ACCESSORIES (“PRODUCTS”) CAN CAUSE DEATH, PERSONAL

INJURY AND PROPERTY DAMAGE. POSSIBLE CONSEQUENCES OF FAILURE OR IMPROPER

SELECTION OR IMPROPER USE OF THESE PRODUCTS INCLUDE BUT ARE NOT LIMITED TO:

• Fittings thrown off at high • Contact with suddenly moving or • Sparking or explosion caused

speed. falling objects that are controlled by static electricity buildup or

• High velocity fluid discharge. by the conveyed fluid. other sources of electricity.

• Explosion or burning of the • Injections by high-pressure fluid • Sparking or explosion while

conveyed fluid. discharge. spraying paint or flammable

• Electrocution from high voltage • Dangerously whipping hose. liquids.

electric powerlines. • Contact with conveyed fluids

that may be hot, cold, toxic or

otherwise injurious.

Before selecting or using any of these products, it is important that you read and follow the instructions below.

Only hose from Parker’s Stratoflex Products Division is approved for in flight aerospace applications, and no other

hose can be used for such in flight applications.

Parker Publication No. 4400-B1 Revised 2007

DO NOT MIX & MATCH

DO NOT MIX & MATCH – • Fittings thrown off at • Only assemble hoses and

Components from different high speed fittings of the same make

manufacturers should not be • High velocity fluid discharge • Always use a crimper

combined to create hose • Fluid injection injury approved by the manufacturer

assemblies (apart from rare • Violently “whipping” hose of the hose and fittings

instances when both • Sparking or explosion from • Crimp only to the manufac-

manufacturers have approved sprayed flammable fluids turer’s specification

the exception). To mix and match • Suddenly moving / falling

components is to increase the objects otherwise held Parker’s recommendations are

risk of hose failure – a dangerous static by fluid pressure consistent with SAE standard

situation regardless of setting J1273: Industry Consensus on

or application. Possible The individual is solely responsible Best Practices for Using

consequences of hose failure for the hose assemblies he or she Hydraulic Hose. The complete

resulting from the use of fabricates. Fluid power profes- technical paper, which includes

incompatible components sionals should abide by three SAE-recommended practices for

include: basic tenets when fabricating hose hose assembly fabrication, can be

assemblies: purchased from www.SAE.org.

4