Page 4 - Exlar - Exlar electric test and simulation actuator systems

P. 4

The Challenge research and creativity is a revo- on industrial equipment

lutionary design which incorpor-

ranging from carpet weaving

ates a high performance machines and machine tools, to

For years, industry has sought

out a clean and effi cient all- brushless servo motor with a simulation and test equipment

electric alternative to hydrau- novel mechanism for converting and submarines. All actuators

portray the unique characteristics

the motor’s power and speed to

lic and pneumatic cylinders. highly accurate and reliable linear of producing the power density,

The promise of such a device motion. speed and robustness of hy-

would be the elimination of the

environmental issues associ- draulic and pneumatic actuation

ated with hydraulic fl uids, the The Result — Since delivering without the inconvenience and

the fi rst actuator to the world’s

operating expense of fl uid power.

noise and inconsistency of leading liquid packaging com-

pneumatics, and a dramatic pany in 1993, the company has

reduction in power consump-

tion. Today, process engineers supplied over 10,000 units of

are facing increasing demands this elegant but simple device

for producing precise, yet highly

for more accurate and better robust linear robust linear mo-

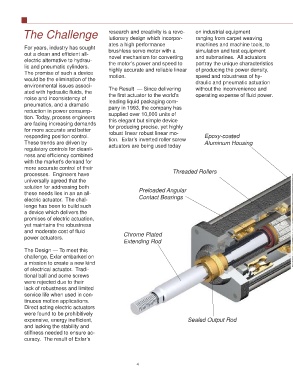

responding position control. tion. Exlar’s inverted roller screw Epoxy-coated

These trends are driven by Aluminum Housing

regulatory controls for cleanli- actuators are being used today

ness and effi ciency combined

with the market’s demand for

more accurate control of their

processes. Engineers have Threaded Rollers

universally agreed that the

solution for addressing both

these needs lies in an an all- Preloaded Angular

electric actuator. The chal- Contact Bearings

lenge has been to build such

a device which delivers the

promises of electric actuation,

yet maintains the robustness

and moderate cost of fl uid

power actuators. Chrome Plated

Extending Rod

The Design — To meet this

challenge, Exlar embarked on

a mission to create a new kind

of electrical actuator. Tradi-

tional ball and acme screws

were rejected due to their

lack of robustness and limited

service life when used in con-

tinuous motion applications.

Direct acting electric actuators

were found to be prohibitively

expensive, energy ineffi cient, Sealed Output Rod

and lacking the stability and

stiffness needed to ensure ac-

curacy. The result of Exlar’s

4