Page 8 - Exlar - Exlar electric test and simulation actuator systems

P. 8

Exlar Features data normally required during test GSX Series

operation. The system accepts

and Options both analog and digital com- Compact

mands. Analog is either 0-10V

Provide or 4-20 mA and can be set up to ElectricTest

Complete control position, velocity or force. Actuators

Multiple forms of position feed-

Alternative to back are available including With form factors similar to

incremental and absolute encod-

Servo ers, resolvers, LVDT or magne- hydraulic cylinders, Exlar’s

torestrictive linear sensors. An

linear actuators provide a

Hydraulic Test integral force sensor can provide compact, integrated

accurate real-time force measure-

motor and actuator

Systems ment while motion is generated. in frame sizes

The same servo amplifi er used from 2 inches

(50mm) to 18 inches

for Exlar’s (200mm) and force

linear ac- outputs of 580 pounds (2570 N)

tuators can to 40,000 pounds (200kN). Exlar

be used actuators are ideal when used

with Exlar’s in applications where cyclic fre-

rotary quency up to 10 Hz and strokes

actuators. are from 0.1 to 10 feet. Exlar’s

All options linear actuators are dimensionally

are avail- similar to fl uid power actuators

able with with standard NFPA front and rear

Exlar rotary clevis mounts which allow, in many

actuators applications, direct substitution for

with the exception of magnetor-

Exlar’s technology is unmatched estrictive LVDT position feedback existing equipment.

by any other electro-mechanical and integrated load cell. Exlar Standard mounting confi gurations

device due to its patented inte- amplifi ers can be interchanged include trunnion and face and

grated roller screw actuator. easily as requirements vary from fl ange mounts, rear clevis, foot and

Additional features such as inte- test to test. side mounts. Custom mounts con-

gral linear position and force fi gured to meet your exact needs

sensors provide test engineers can be designed and built.

with reliable, dynamic data.

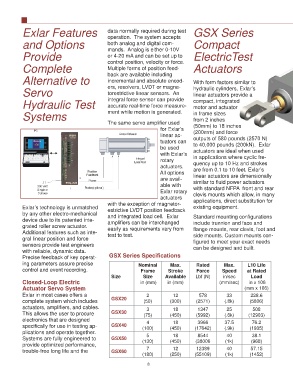

Precise feedback of key operat- GSX Series Specifi cations

ing parameters assure precise Nominal Max. Rated Max. L10 Life

control and event recording. Frame Stroke Force Speed at Rated

Size Size Available Lbf (N) in/sec Load

Closed-Loop Electric in (mm) in (mm) (mm/sec) in x 106

Actuator Servo System (mm x 106)

Exlar in most cases offers a 2 12 578 33 228.6

complete system which includes GSX20 (50) (300) (2571) (.8k) (5806)

actuators, amplifi ers, and cables. 3 18 1347 25 508

This allows the user to procure GSX30 (75) (450) (5992) (.6k) (12903)

electronics that are designed 4 18 3966 37.5 76.2

specifi cally for use in testing ap- GSX40 (100) (450) (17642) (.9k) (1935)

plications and operate together.

18

38.1

8544

40

5

Systems are fully engineered to GSX50 (130) (450) (38006 (1k) (968)

provide optimized performance,

trouble-free long life and the GSX60 7 12 12389 40 57.15

(180) (250) (55109) (1k) (1452)

8