Page 2 - Linde - Model code edition X-02 series product

P. 2

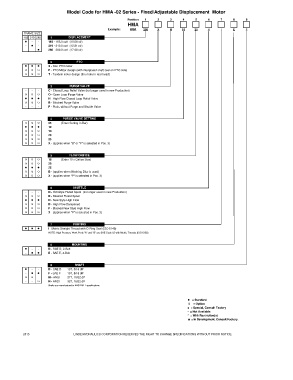

Model Code for HMA -02 Series - Fixed/Adjustable Displacement Motor

Position 1 2 3 4 5 6 7 8 9

HMA

Example: HMA 280 X H 10 25 H I E F

FRAME SIZE

165 210 280 1 DISPLACEMENT

l - - 165 - 165.0 cc/r (10.06 cir)

- l - 210 - 210.0 cc/r (12.81 cir)

- - l 280 - 280.0 cc/r (17.08 cir)

2 PTO

l l l X - Non-PTO motor

m m m P - PTO Motor design (with intergrated shaft seal on PTO side)

m m m T - Tandem motor design (thru hole in rear head)

3 PURGE VALVE

- - - C - Closed Loop Relief Valve (no longer used in new Production)

m m m O - Open Loop Purge Valve

l l l H - High Flow Closed Loop Relief Valve

m m m B - Blocked Purge Valve

- - - P - Plain, without Purge and Shuttle Valve

4 PURGE VALVE SETTING

m m m 05 (Enter Setting in Bar)

l l l 10

m m m 14

m m m 20

m m m 25

m m m X - (applies when "B" or "P" is selected in Pos. 3)

5 FLOW ORIFICE

m m m 18 (Enter 10 x Orifice Size)

m m m 20

l l l 25

m m m B - (applies when Blocking Disc is used)

m m m X - (applies when "P" is selected in Pos. 3)

6 SHUTTLE

- - - N - Old Style Fluted Spool (no longer used in new Production)

m m m B - Blocked Fluted Spool

l l l H - New Style High Flow

m m m D - High Flow Dampened

m m m P - Blocked New Style High Flow

m m m X - (applies when "P" is selected in Pos. 3)

7 PORTING

l l l I - Metric Straight Thread with O-Ring Seal (ISO 6149)

NOTE: High Pressure Work Ports "A" and "B" are SAE Code 62 with Metric Threads (ISO 6162)

8 MOUNTING

l - - D - SAE D, 2-Bolt

- l l E - SAE E, 4-Bolt

9 SHAFT

l - - D - SAE D 13T, 8/16 dP

- l l F - SAE F 15T, 8/16 dP

m m - M - ANSI 27T, 16/32 dP

- - m N - ANSI 33T, 16/32 dP

Shafts are manufactured to ANSI B92.1 specifications

l = Standard

m = Option

c = Special, Consult Factory

- = Not Available

* = With Restriction(s)

p = In Development. Consult Factory.

2015 LINDE HYDRAULICS CORPORATION RESERVES THE RIGHT TO CHANGE SPECIFICATIONS WITHOUT PRIOR NOTICE.