Page 2 - Parker - Coatings

P. 2

The Parker Solution

The DuraBond™ cartridge was

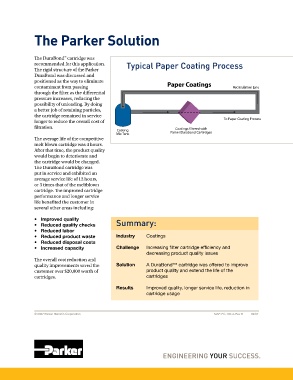

recommended for this application. Typical Paper Coating Process

The rigid structure of the Parker

DuraBond was discussed and

positioned as the way to eliminate

contaminant from passing

through the filter as the differential

pressure increases, reducing the

possibility of unloading. By doing

a better job of retaining particles,

the cartridge remained in service

longer to reduce the overall cost of

filtration.

The average life of the competitive

melt blown cartridge was 4 hours.

After that time, the product quality

would begin to deteriorate and

the cartridge would be changed.

The DuraBond cartridge was

put in service and exhibited an

average service life of 12 hours,

or 3 times that of the meltblown

cartridge. The improved cartridge

performance and longer service

life benefited the customer in

several other areas including:

• Improved quality

• Reduced quality checks Summary:

• Reduced labor

• Reduced product waste Industry Coatings

• Reduced disposal costs

• Increased capacity Challenge Increasing filter cartridge efficiency and

decreasing product quality issues

The overall cost reduction and

quality improvements saved the Solution A DuraBond™ cartridge was offered to improve

customer over $20,000 worth of product quality and extend the life of the

cartridges. cartridges

Results Improved quality, longer service life, reduction in

cartridge usage

© 2007 Parker Hannifin Corporation MAP-PC-100-A-Rev B 09/07