Page 1 - Parker - Inks, paints and coatings product line

P. 1

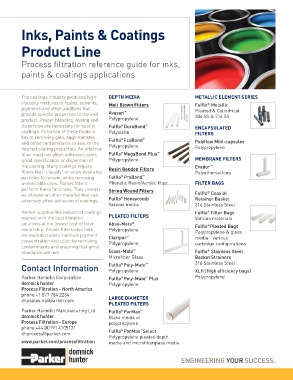

Inks, Paints & Coatings

Product Line

Process fi ltration reference guide for inks,

paints & coatings applications

The coatings industry produces high- DEPTH MEDIA METALLIC ELEMENT SERIES

viscosity mixtures of resins, solvents, Melt Blown Filters Fulfl o Metallic

®

pigments and other additives that Pleated & Cylindrical

provide specifi c properties to the end Avasan ™ 304 SS & 316 SS

product. Proper blending, mixing and Polypropylene

dispersion are necessary for quality Fulfl o DuraBond ™ ENCAPSULATED

®

coatings. Filtration of these fl uids is Polyolefi n FILTERS

key to removing gels, agglomerates Fulfl o EcoBond ™

®

and other contaminants to assure the Polypropylene Polyfl ow Mini-capsules

desired coating properties. An effective Polypropylene

®

fi lter must not affect adhesion, color, Fulfl o MegaBond Plus ™

grind specifi cation or dispersion of Polypropylene MEMBRANE FILTERS

the coating. Many coatings require Evadur ™

fi lters that “classify” or allow desirable Resin Bonded Filters Polyethersulfone

®

particles to remain, while removing Fulfl o ProBond ™

undesirable ones. Parker fi lters Phenolic Resin/Acrylic fi ber FILTER BAGS

perform these functions. They contain String Wound Filters

®

no silicone or other material that can ® Fulfl o Coaxial

adversely affect adhesion of coatings. Fulfl o Honeycomb Retainer Basket

Various media 316 Stainless Steel

Parker supplies the industrial coatings Fulfl o Filter Bags

®

market with the best fi ltration PLEATED FILTERS Various materials

solutions at the lowest cost of fi lter Abso-Mate ® Fulfl o Pleated Bags

®

ownership. Parker fi lters also help Polypropylene Polypropylene & glass

ink manufacturers maintain pigment Claripor ™ media - various

concentration and color, by removing Polypropylene cartridge confi gurations

contaminants and ensuring that grind

®

standards are met. Glass-Mate ™ Fulfl o Stainless Steel

Microfi ber Glass Basket Strainers

®

Contact Information Fulfl o Poly-Mate ™ 316 Stainless Steel

Polypropylene

XLH (High effi ciency bags)

Parker Hannifi n Corporation Fulfl o Poly-Mate Plus Polypropylene

™

®

domnick hunter Polypropylene

Process Filtration - North America

phone +1 877 784 2234 LARGE DIAMETER

dhpsales.na@parker.com

PLEATED FILTERS

Parker Hannifi n Manufacturing Ltd Fulfl o ParMax ™

®

domnick hunter Glass media or

Process Filtration - Europe polypropylene

phone +44 (0)191 4105121 Fulfl o ParMax Select

®

™

dhprocess@parker.com

Polypropylene pleated depth

www.parker.com/processfi ltration media and microfi berglass media

ENGINEERING YOUR SUCCESS.