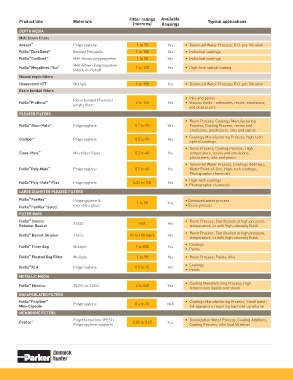

Page 3 - Parker - Inks, paints and coatings product line

P. 3

Filter ratings Available

Product line Materials Typical applications

(microns) Housings

DEPTH MEDIA

Melt blown fi lters

Avasan ™ Polypropylene 1 to 75 Yes • Deionized Water Process; R.O. pre-filtration

®

Fulfl o DuraBond ™ Bonded Polyolefin 1 to 100 Yes • Industrial coatings

®

Fulfl o EcoBond ™ Melt-blown polypropylene 1 to 50 Yes • Industrial coatings

Melt-Blown Polypropylene

®

Fulfl o MegaBond Plus ™ 1 to 120 Yes • High-tech optical coating

(Absolute-Rated)

Wound depth fi lters

Honeycomb HFT Multiple 1 to 150 Yes • Deionized Water Process; R.O. pre-filtration

Resin bonded fi lters

• Inks and paints

Resin bonded Phenolic/

®

Fulfl o ProBond ™ 2 to 150 Yes • Viscous fl uids - adhesives, resins, emulsions,

acrylic fi ber

and plasticizers

PLEATED FILTERS

• Resin Process, Coatings Manufacturing

®

Fulfl o Abso-Mate ™ Polypropylene 0.2 to 70 Yes Process, Coating Process; resins and

emulsions, plasticizers, inks and paints

• Coatings Manufacturing Process; high-tech

Claripor ™ Polypropylene 0.5 to 90 Yes

optical coatings

• Resin Process, Coating Process; High

Glass-Mate ™ Microfiber Glass 0.2 to 40 Yes temperature, resins and emulsions,

plasticizers, inks and paints

• Deionized Water Process, Coatings Additives;

®

Fulfl o Poly-Mate ™ Polypropylene 0.5 to 60 Yes Water Point-of-Use, High-tech coatings,

Photographic chemicals

• High-tech coatings

®

™

Fulfl o Poly-Mate Plus Polypropylene 0.25 to 100 Yes

• Photographic chemicals

LARGE DIAMETER PLEATED FILTERS

Fulfl o ParMax ™ Polypropylene & • Deionized water process

®

microfiberglass 1 to 90 Yes • Resin process

™

®

Fulfl o ParMax Select

FILTER BAGS

®

Fulfl o Coaxial • Resin Process; Clarifi cation at high pressure,

Retainer Basket 316SS N/A Yes temperature, or with high-viscosity fl uids

• Resin Process; Clarifi cation at high pressure,

®

Fulfl o Basket Strainer 316SS 20 to 100 mesh Yes

temperature, or with high-viscosity fl uids

• Coatings

®

Fulfl o Filter Bag Multiple 1 to 800 Yes

• Paints

®

Fulfl o Pleated Bag Filter Multiple 1 to 90 Yes • Resin Process; Paints, Inks

• Coatings

®

Fulfl o XLH Polypropylene 0.5 to 25 Yes

• Paints

METALLIC MEDIA

• Coating Manufacturing Process; High

®

Fulfl o Metallic 304SS or 316SS 2 to 840 Yes

temperature liquids and steam

ENCAPSULATED FILTERS

®

™

Fulfl o Polyfl ow Polypropylene 0.6 to 10 N/A • Coatings Manufacturing Process; Small batch

Mini-Capsule ink operations requiring low hold-up volume

MEMBRANE FILTERS

Polyethersulfone (PES) / • Deionization Water Process, Coating Additives,

Evadur ™ 0.03 to 0.65 Yes

Polypropylene supports Coating Process; inks fi nal fi ltration