Page 6 - Parker- Parker global air preparation system

P. 6

Catalog 0750-3 US Parker Global Air Preparation Products Catalog 0750-3 US Parker Global Air Preparation Products

Global Air Preparation System Introduction Global Air Preparation System Introduction

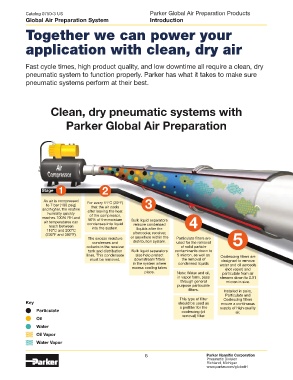

Together we can power your

application with clean, dry air

Fast cycle times, high product quality, and low downtime all require a clean, dry

pneumatic system to function properly. Parker has what it takes to make sure Stages 1 2 3 4 5 6 7

pneumatic systems perform at their best.

Function Air Compressor Bulk Liquid Particulate Coalescing Air Dryers Hydrocarbon

Removal Filtration Filtration Removal

All pneumatic Basic pneumatic Basic pneumatic Systems requiring Systems requiring Systems requiring

Application systems systems systems highest quality air. air with reduced highest quality air for

Clean, dry pneumatic systems with Air leaving the Removes bulk Removes solid Removes liquid moisture content critical applications

Removal of odors

Removes water

Parker Global Air Preparation Description compressor room at liquid contamination particulates down to aerosols and vapor from air and trace vapors for

submicron

5 micron, and

93ºC (200ºF) releases and protects filters

stream. Dew point

critical applications.

95% of its moisture

reduced down to 4ºC

particulates (not

where excess cooling the separation of

into the piping takes place in the bulk contaminants. vapor) down to (40ºF) (refrigeration)

system when it cools distribution piping 0.01 micron. or -40ºC (-40ºF)

to 38ºC (100ºF) (desiccant).

Parker Customer P3TF P31, P32, P33 P31, P32, P33 PRD Refrigeration P31, P32, P33

Global Air supplied Bulk Liquid Particulate Filter Coalescing Filter Dryer, DAS & PTW Activated Carbon

Preparation Separator Regenerative (Adsorber) Filter

Solution Desiccant Dryer

1

Stage 2

As air is compressed For every 11°C (20°F) 3

to 7 bar (100 psig)

that the air cools

and higher, the relative after leaving the heat

humidity quickly of the compressor,

reaches 100% RH and 50% of the moisture

air temperatures can condenses into liquid Bulk liquid separators 4

reach between remove condensed

110°C and 200°C into the system. liquids after the

(230°F and 392°F). aftercooler, receiver, Clean

The excess moisture or anywhere within the Particulate filters are 5

condenses and distribution system. used for the removal

collects in the receiver of solid particle

tank and distribution Bulk liquid separators contaminants down to

lines. This condensate also help protect 5 micron, as well as Coalescing filters are Dry Air

must be removed. downstream filters the removal of designed to remove

in the system where condensed liquids water and oil aerosols

excess cooling takes (not vapor) and

place. Note: Water and oil, particulate from air

in vapor form, pass streams down to 0.01

through general micron in size. 6

purpose particulate

filters. Installed in pairs,

Particulate and

This type of filter Coalescing filters

Refrigeration and

Key should be used as ensure a continuous lower the air's dew 7

a prefilter for the supply of high quality desiccant dryers

Particulate coalescing (oil air.

removal) filter. point by removing

Oil water vapor, providing Hydrocarbon and oil

appropriately dry air vapors are removed

Water for the downstream using filters utilizing

application.

activated carbon.

Oil Vapor Airborne hydrocarbons

Water Vapor are often left over from

the compressor oils.

6 Parker Hannifin Corporation 7 Parker Hannifin Corporation

Pneumatic Division Pneumatic Division

Richland, Michigan Richland, Michigan

www.parker.com/globalfrl www.parker.com/globalfrl