Page 25 - Parker - Process filtration

P. 25

™

Glass-Mate Cartridges

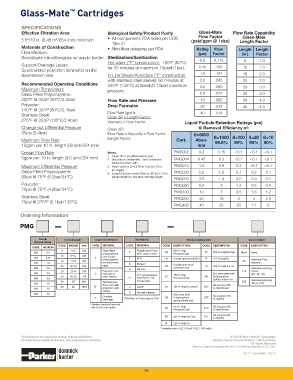

SPECIFICATIONS

Glass-Mate

Effective Filtration Area Biological Safety/Product Purity Flow Factor Flow Rate Capability

Glass-Mate

2

5 ft /10 in. (0.46 m /254 mm) minimum • All components FDA listed per CFR, (psid/gpm @ 1cks) Length Factor

2

Title 21

Materials of Construction • Non-fi ber releasing per FDA Rating Flow Length Length

Filter Medium: (μm) Factor (in.) Factor

Borosilicate microfi berglass w/ acrylic binder Sterilization/Sanitization

Hot water (“F” construction): 180°F (82°C) 0.2 0.115 9 1.0

Support/Drainage Layers: for 30 minutes at maximum 15psid (1bar). 0.45 .108 10 1.0

Spunbonded polyester; laminated on the

downstream side In-Line Steam/Autoclave (“F” construction 1.0 .102 19 2.0

with stainless steel sleeve): 60 minutes at 2.0 .095 20 2.0

Recommended Operating Conditions 255°F (140°C) at 2psid (0.14bar) maximum 3.0 .090

Maximum Temperature pressure. 29 3.0

Glass Filled Polypropylene: 5.0 .072 30 3.0

200°F @ 35ΔP (93°C/2.4bar) Flow Rate and Pressure 10 .060 39 4.0

Polyester: Drop Formulas 20 .042 40 4.0

140°F @ 35ΔP (60°C/2.4bar)

Flow Rate (gpm): 40 .018

Stainless Steel: Clean ΔP x Length Factor

275°F @ 35ΔP (135°C/2.4bar) Viscosity x Flow Factor Liquid Particle Retention Ratings (μm)

Change-out Differential Pressure Clean ΔP: @ Removal Effi ciency of:

35psi (2.4bar) Flow Rate x Viscosity x Flow Factor ß=5000

Length Factor ß=1000 ß=100 ß=20 ß=10

Maximum Flow Rate Cart. Abso- 99.8% 99% 95% 90%

10gpm per 10 in. length (38 lpm/254 mm) lute

Design Flow Rate Notes: PMG002 0.2 0.15 <0.1 <0.1 <0.1

1. Clean ΔP is psi differential at start.

5gpm per 10 in. length (9.5 lpm/254 mm)

2. Viscosity is centistokes. Use Conversion PMG004 0.45 0.3 <0.1 <0.1 <0.1

Tables for other units.

Maximum Differential Pressure 3. Flow Factor is ΔP/GPM at 1cks for 10 in. PMG010 1.0 0.6 0.2 <0.1 <0.1

(or single).

Glass-Filled Polypropylene: 4. Length Factors convert fl ow or ΔP from 10 in. PMG020 2.0 1.2 0.4 0.2 0.1

90psi @ 75°F (6.2bar/24°C) (single length) to required cartridge length.

PMG030 3.0 1.8 0.6 0.3 0.2

Polyester: PMG050 5.0 3 1.3 0.5 0.4

70psi @ 75°F (4.8bar/24°C)

PMG100 10 7 3.5 1.6 1.2

Stainless Steel: PMG200 20 16 8 4 2.5

75psi @ 275°F (5.1bar/135°C)

PMG400 40 32 20 11 8

Ordering Information

PMG — —

Particle Nominal Length Support Construction Seal Material End Cap Confi guration Special Options

Removal Rating

CODE INCHES mm CODE MATERIAL CODE MATERIAL CODE DESCRIPTION CODE DESCRIPTION CODE DESCRIPTION

CODE MICRON

5

9 9 ⁄ 8 ˝ 244 Glass-fi lled Polyethylene Foam 020 O-ring/

002 0.2 P AR TC 222 O-ring/Flat Cap Blank None

polypropylene (DOE gasket only) Recessed cap

10 9 13 ⁄16 ˝ 249

004 0.45 F core & pure E EPR DO Double open end (DOE) TF 222 O-ring/Fin

19 19 5 ⁄ 8 ˝ 498 polypropylene Z6 Individual Poly

010 1.0 extruded outer N Buna-N bag only

20 19 15 ⁄16 ˝ 506 cage DX Double open end/ TX 222 O-ring/Flex Fin

020 2.0 S Silicone extended core Individual poly bag

29 29 ¼ ˝ 743 Polyester core, Z15 15/ctn.

030 3.0 P end caps & PFA Encapsulated 120 O-ring/ Ext. core open end/ (20˝, 30˝, 40˝)

30 30 1 ⁄16 ˝ 764 outer netting LL 3 XB Polypropylene

050 5.0 T 2 Viton ® (222, 226 Recessed Cap spring closed end

39 39 ˝ 991 304 Stainless O-ring only) Z30 Individual poly bag

100 10 Steel core with SS inserted 226 30/ctn. (10˝)

40 40 ˝ 1016 G 1 V Viton ® LR 120 O-ring/Recessed 3 SSC

200 20 polyester outer O-ring/Closed

netting

X No seal material

400 40 Std. open end/

Coreless SS inserted 226

X 2 PFA/Viton is O-ring only; for DOE OB Polypropylene SSF

Cartridge spring closed end O-ring/Fin

1 Stainless steel end caps incl.

only on DO code option PR 213 O-ring/ STC SS inserted 222

Recessed cap 3 O-ring/Closed

SS inserted 222

SC 226 O-ring/Flat Cap STF

O-ring/Fin

SF 226 O-ring/Fin

3 Available only in 9 5 ⁄ 8 ˝ (-9) and 19 5 ⁄ 8 ˝ (-19) lengths

Specifi cations are subject to change without notifi cation. © 2010 Parker-Hannifi n Corporation

For User Responsibility Statement, see www.parker.com/safety domnick hunter Process Filtration - North America

All Rights Reserved

Viton is a registered trademark of E.I. DuPont de Nemours & Co., Inc.

DS_IP_Glass-Mate Rev. A

25