Page 27 - Parker - Process filtration

P. 27

®

Fulfl o 336 Pleated Cartridges

SPECIFICATIONS

Materials of Construction

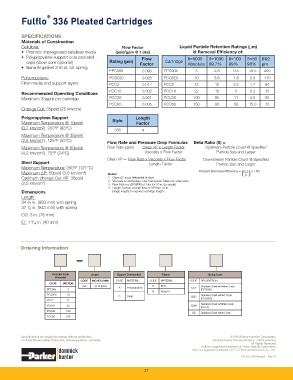

Cellulose: Flow Factor Liquid Particle Retention Ratings (μm)

• Phenolic impregnated cellulose media (psid/gpm @ 1 cks) @ Removal Effi ciency of:

• Polypropylene support core and end Flow ß=5000 ß=1000 ß=100 ß=50 ß@2

caps (Steel core optional) Rating (μm) Factor Cartridge Absolute 99.7% 99% 98% μm

• Buna-N gasket 316 st. stl. spring

PPC005 0.090 PPC005 3 2.8 0.5 <0.5 400

Polypropylene: PCG020 0.026 PCG020 10 8.6 1.8 0.9 110

Filter media and support layers PCC2 0.017 PCC2 12 10 3.2 1.7 64

PCC10 0.002 PCC10 22 18 6 3.2 35

Recommended Operating Conditions

Maximum 33gpm per cartridge PCC30 0.001 PCC30 100 85 11 4.5 25

PCC60 0.005 PCC60 150 90 30 15.0 10

Change Out: 35psid (25 km/cm)

Polypropylene Support Length

Style

Maximum Temperature @ 10psid Factor

2

(0.7 km/cm ): 200°F (93°C)

336 4

Maximum Temperature @ 35psid

2

(2.5 km/cm ): 125°F (52°C)

Flow Rate and Pressure Drop Formulas Beta Ratio (ß) =

Maximum Temperature @ 60psid Flow Rate (gpm) = Clean ΔP x Length Factor Upstream Particle Count @ Specifi ed

2

(4.2 km/cm ): 75°F (24°C) Viscosity x Flow Factor Particle Size and Larger

Clean ΔP = Flow Rate x Viscosity x Flow Factor Downstream Particle Count @ Specifi ed

Steel Support Length Factor Particle Size and Larger

Maximum Temperature: 250°F (121°C)

Percent Removal Effi ciency = ß-1 x 100

Maximum ΔP: 50psid (3.5 km/cm ) Notes: ( )

2

ß

Optimum change Out ΔP: 35psid 1. Clean ΔP is psi differential at start.

2. Viscosity is centistokes. Use Conversion Tables for other units.

2

(2.5 km/cm ) 3. Flow Factor is ΔP/GPM at 1cks for 10 in. (or single).

4. Length Factors convert fl ow or ΔP from 10 in.

Dimensions (single length) to required cartridge length.

Length:

34 ¾ in. (883 mm) w/o spring

1

37 ⁄ 8 in. (943 mm) with spring

OD: 3 in. (76 mm)

9

ID: 1 ⁄ 16 in. (40 mm)

Ordering Information

—

Cartridge Code Length Support Construction Gasket Spring Code

(Absolute)

CODE INCHES (MM) CODE MATERIAL CODE MATERIAL CODE DESCRIPTION

CODE MICRON

336 34 ¾ (883) A Polypropylene E EPR Stainless Steel w/Yellow Code

PPC005 3 GSY (PPC005)

N Buna-N

PCG020 10 Stainless Steel w/Red Code

C Steel GSR

(PCG020)

PCC2 12

Stainless Steel w/White Code

PCC10 22 GSW

(PCC2)

PCC30 100

GS Stainless Steel w/No Code

PCC60 150

Specifi cations are subject to change without notifi cation. © 2010 Parker-Hannifi n Corporation

For User Responsibility Statement, see www.parker.com/safety domnick hunter Process Filtration - North America

All Rights Reserved

Fulfl o is a registered trademark of Parker-Hannifi n Corporation

Viton is a registered trademark of E.I. DuPont de Nemours & Co., Inc.

DS_IP_336 Pleated Rev. A

27