Page 61 - Parker - Pressure Control Valves

P. 61

Catalog HY15-3502/US Direct Acting, Cross-over Relief Valve

Technical Information Series A04J2

CV

General Description

Direct Acting, Dual Poppet-Type, Cross-over Relief

Valve. For additional information see Technical Tips

Valves

Check

SH on pages PC1-PC6.

Features

• Compact space saving design

Valves

Shuttle

• Cost effective - only requires one cavity

LM

• Poppet-type construction for lower leakage

• Full 350 Bar, 5000 PSI pressure capability

• High flow capability for the size of valve

Load/Motor

Controls

FC • Minimal pressure variation with flow change

• Hardened working parts for maximum durability

(1) (2)

• Adjustable and tamperproof versions available

• Available as CE marked valve in compliance with

Flow

Controls

PC Pressure Equipment Directive

(2)

• All external parts zinc plated

Specifications

Controls

Pressure

(1)

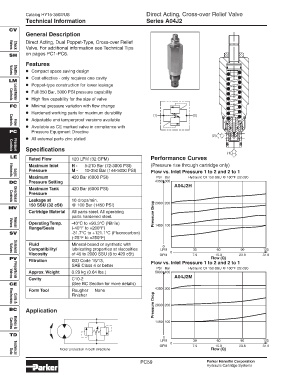

LE Performance Curves

Rated Flow 120 LPM (32 GPM)

Maximum Inlet H - 5-210 Bar (72-3000 PSI) (Pressure rise through cartridge only)

Pressure M - 10-350 Bar (144-5000 PSI) Flow vs. Inlet Pressure 1 to 2 and 2 to 1

Maximum 420 Bar (6000 PSI) PSI Bar Hydraulic Oil 150 SSU @ 100°F (32 cSt)

Logic

Elements

DC Pressure Setting 4350 300

A04J2H

Maximum Tank 420 Bar (6000 PSI)

Pressure

Leakage at 10 drops/min. 2900 200

Directional

Controls

150 SSU (32 cSt) @ 100 Bar (1450 PSI)

MV

Cartridge Material All parts steel. All operating Pressure Drop

parts hardened steel.

Operating Temp. -40°C to +93.3°C (Nitrile) 1450 100

Range/Seals (-40°F to +200°F)

Valves

Manual

SV -31.7°C to +121.1°C (Fluorocarbon)

(-25°F to +250°F)

Fluid Mineral-based or synthetic with

0

Compatibility/ lubricating properties at viscosities LPM 30 60 90 120

0

Viscosity of 45 to 2000 SSU (6 to 420 cSt) GPM 7.9 15.9 23.8 31.8

Solenoid

Valves

PV Flow (Q)

Filtration ISO Code 16/13, Flow vs. Inlet Pressure 1 to 2 and 2 to 1

SAE Class 4 or better

PSI Bar Hydraulic Oil 150 SSU @ 100°F (32 cSt)

Approx. Weight 0.29 kg (0.64 lbs.) 5800 400

A04J2M

Cavity C10-2

Proportional

Valves

CE (See BC Section for more details)

4350 300

Form Tool Rougher None

Pressure Drop 2900 200

Finisher

Electronics

Coils &

BC Application

1450 100

Cavities

Bodies &

TD

0

LPM 30 60 90 120

0

GPM 7.9 15.9 23.8 31.8

Motor protection in both directions Flow (Q)

Data

Technical

PC59 Parker Hannifin Corporation

Hydraulic Cartridge Systems