Page 10 - Parker - Proportional Valves

P. 10

Catalog HY15-3502/US Proportional Relief Valve

Technical Information Series AP02B2YP 07C, 14C, 21C, 35C

CV

General Description

Proportional Relief Valve. Increasing Pressure With

Increasing Current. For additional information see

Valves

Check

SH Technical Tips on pages PV1-PV6.

Features

• Analog Proportional Relief Valve regulates pressure

proportionally to the solenoid current

Shuttle

Valves

LM

• Direct acting poppet design

• One piece cartridge housing ensures internal

concentricity

• Coil: Waterproof, hermetically sealed, requires no (2)

Controls

Load/Motor

FC O’Rings; Symmetrical coil can be reversed without

affecting performance.

(1) (2)

(1)

NOTE:

Controls

Flow

PC This valve will be available January 1, 2011.

Specifications

Pressure

Controls

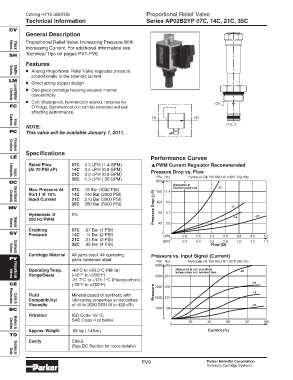

LE Performance Curves

Rated Flow 07C 5.3 LPM (1.4 GPM) PWM Current Regulator Recommended

(At 70 PSI ∆∆ ∆∆ ∆P) 14C 3.4 LPM (0.9 GPM) Pressure Drop vs. Flow

21C 3.0 LPM (0.8 GPM)

PSI Bar Hydraulic Oil 150 SSU @ 100°F (32 cSt)

Elements

Logic

35C 1.3 LPM (.35 GPM) 200 14.3

DC

Measured at

De-energized coil -35

Max. Pressure At 07C 70 Bar (1000 PSI) P) 160 11.4

Port 1 @ 75% 14C 140 Bar (2000 PSI)

Input Current 21C 210 Bar (3000 PSI) 120 8.6

Directional

Controls

35C 350 Bar (5000 PSI)

MV Pressure Drop ( -21

Hysteresis @ 5% 80 5.7 -07

200 Hz PWM 40 2.0 -14

Valves

Manual

Cracking 07C .07 Bar (1 PSI)

SV Pressure 14C .14 Bar (2 PSI) 0 LPM 0.8 1.5 2.3 3.0 3.8 4.5 5.3

21C .21 Bar (3 PSI) 0

GPM 0.2 0.4 0.6 0.8 1.0 1.2 1.4

35C .35 Bar (4 PSI) Flow (Q)

Valves

Solenoid

Cartridge Material All parts steel. All operating Pressure vs. Input Signal (Current)

PV parts hardened steel.

PSI Bar Hydraulic Oil 150 SSU @ 100°F (32 cSt)

5000 345

Operating Temp. -40°C to +93.3°C (Nitrile) Measured at coil stabilized -35

temperature and nominal flow

Range/Seals (-40°F to +200°F) 4000 274

-31.7°C to +121.1°C (Fluorocarbon)

Valves

Proportional

CE (-25°F to +250°F) 3000 205 -21

Pressure -14

Fluid Mineral-based or synthetic with 2000 137

Compatibility/ lubricating properties at viscosities

Viscosity of 45 to 2000 SSU (6 to 420 cSt) -07

Electronics

Coils &

BC 1000 68

Filtration ISO Code 16/13,

0

SAE Class 4 or better 20 40 60 80 100

0

Bodies &

Approx. Weight .06 kg (.14 lbs.) Current (%)

Cavities

TD

Cavity C08-2

(See BC Section for more details)

Technical

Data

PV9 Parker Hannifin Corporation

Hydraulic Cartridge Systems