Page 82 - Parker - Rodless Air Cylinders

P. 82

Catalog #AU03-0928/NA Rodless Magnetic Cylinders

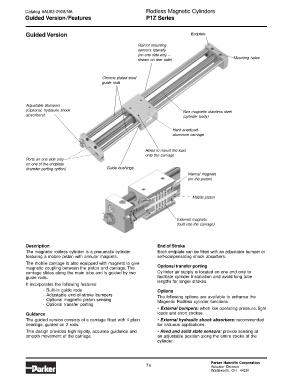

Guided Version/Features P1Z Series

Guided Version Endplate

Rail for mounting

sensors laterally

(on one side only –

shown on rear side) Mounting holes

Chrome plated steel

guide rods

Adjustable Bumpers

(Optional: hydraulic shock

Non magnetic stainless steel

absorbers)

(cylinder body)

Hard anodized

aluminum carriage

Holes to mount the load

onto the carriage

Ports on one side only

on one of the endplate

(transfer porting option) Guide bushings

Internal magnets

(on the piston)

Mobile piston

External magnets

(built into the carriage)

Description End of Stroke

The magnetic rodless cylinder is a pneumatic cylinder Each endplate can be fitted with an adjustable bumper or

featuring a mobile piston with annular magnets. self-compensating shock absorbers.

The mobile carriage is also equipped with magnets to give

magnetic coupling between the piston and carriage. The Optional transfer porting

carriage slides along the main tube and is guided by two Cylinder air supply is located on one end only to

guide rods. facilitate cylinder installation and avoid long tube

lengths for longer strokes.

It incorporates the following features:

- Built-in guide rods Options

- Adjustable end-of-stroke bumpers The following options are available to enhance the

- Optional magnetic piston sensing Magnetic Rodless cylinder functions:

- Optional transfer porting

• External bumpers: when low operating pressure, light

Guidance loads and short strokes.

The guided version consists of a carriage fitted with 4 plain • External hydraulic shock absorbers: recommended

bearings, guided on 2 rods. for arduous applications.

This design provides high rigidity, accurate guidance and • Reed and solid state sensors: provide sensing at

smooth movement of the carriage. an adjustable position along the entire stroke of the

cylinder.

Parker Hannifin Corporation

74 Actuator Division

Wadsworth, OH 44281