Page 2 - Eaton - Standard Cast Pipeline Strainers

P. 2

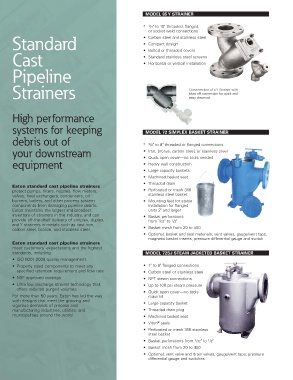

MODEL 85 Y STRAINER

• 1 /4" to 10" threaded, flanged,

or socket weld connections

Standard • Carbon steel and stainless steel

• Compact design

• Bolted or threaded covers

Cast • Standard stainless steel screens

• Horizontal or vertical installation

Pipeline

Strainers Cross-section of a Y Strainer with

blow off connection for quick and

easy clean-out.

High performance

systems for keeping MODEL 72 SIMPLEX BASKET STRAINER

debris out of • 3 /8" to 8" threaded or flanged connections

your downstream • Iron, bronze, carbon steel, or stainless steel

• Quick open cover—no tools needed

equipment • Heavy wall construction

• Large capacity baskets

• Machined basket seat

• Threaded drain

Eaton standard cast pipeline strainers

protect pumps, filters, nozzles, flow meters, • Perforated or mesh 316

valves, heat exchangers, condensers, oil stainless steel basket

burners, boilers, and other process system • Mounting feet for stable

components from damaging pipeline debris. installation for flanged

Eaton maintains the largest and broadest units 2" and larger

inventory of strainers in the industry, and can • Basket perforations

provide off-the-shelf delivery of simplex, duplex, from 1 /32" to 1 /2"

and Y strainers in metals such as cast iron,

carbon steel, bronze, and stainless steel. • Basket mesh from 20 to 400

• Optional: basket and seal materials, vent valves, gauge/vent taps,

magnetic basket inserts, pressure differential gauge and switch

Eaton standard cast pipeline strainers

meet customers’ expectations and the highest

standards, including: MODEL 72SJ STEAM JACKETED BASKET STRAINER

• ISO 9001-2008 quality management

• Properly sized components to meet any • 1" to 8" flanged connections

specified retention requirement and flow rate • Carbon steel or stainless steel

• NSF approved coatings • NPT steam connections

• Ultra low discharge strainer technology that • Up to 100 psi steam pressure

offers reduced purged volumes • Quick open cover—no tools

For more than 50 years, Eaton has led the way required

with designs that meet the growing and • Large capacity basket

vigorous demands of process and

manufacturing industries, utilities, and • Threaded drain plug

municipalities around the world. • Machined basket seat

®

• Viton seals

• Perforated or mesh 316 stainless

steel basket

• Basket perforations from 1 /32" to 1 /2"

• Basket mesh from 20 to 400

• Optional: vent valve and drain valves, gauge/vent taps, pressure

differential gauge and switches