Page 57 - Exlar - TRITEX 2 series fully integrated servo drive/motor/actuator

P. 57

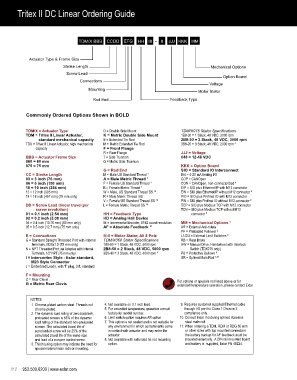

Tritex II DC Linear Ordering Guide

Sample Product Number: TDM075-1004-NCW-IE-2B8-30-048-CON-SD-XL

TDM/X BBB CCDD EFG HH III - II JJJ KKK MM

Actuator Type & Frame Size

Stroke Length Mechanical Options

Screw Lead

Option Board

Connections

Voltage

Mounting Motor Stator

Rod End Feedback Type

Commonly Ordered Options Shown in BOLD

TDM/X = Actuator Type D = Double Side Mount TDM/X075 Stator Specifications

TDM = Tritex II Linear Actuator, K = Metric Double Side Mount 1B8-30 = 1 Stack, 48 VDC, 3000 rpm

standard mechanical capacity E = Extended Tie Rod 2B8-30 = 2 Stack, 48 VDC, 3000 rpm

TDX = Tritex II Linear Actuator, high mechanical M = Metric Extended Tie Rod 3B8-20 = 3 Stack, 48 VDC, 2000 rpm 4

capacity F = Front Flange

R = Rear Flange JJJ = Voltage

BBB = Actuator Frame Size T = Side Trunnion 048 = 12-48 VDC

060 = 60 mm Q = Metric Side Trunnion

075 = 75 mm KKK = Option Board

G = Rod End SIO = Standard IO Interconnect

CC = Stroke Length M = Male US Standard Thread 1 IA4 = 4-20 mA Analog I/O

03 = 3 inch (76 mm) A = Male Metric Thread 1 COP = CANOpen

06 = 6 inch (150 mm) F = Female US Standard Thread 1 CON = CANOpen, non-connectorized 9

10 = 10 inch (254 mm) B = Female Metric Thread 1 EIP = SIO plus Ethernet/IP with M12 connector

12 = 12 inch (305 mm) W = Male, US Standard Thread SS 10 EIN = SIO plus Ethernet/IP without M12 connector 9

18 = 18 inch (457 mm) (75 mm only) R = Male Metric Thread SS PIO = SIO plus Profinet IO with M12 connector

V = Female US Standard Thread SS 10 PIN = SIO plus Profinet IO without M12 connector 9

DD = Screw Lead (linear travel per L = Female Metric Thread SS 10 TCP = SIO plus Modbus TCP with M12 connector

screw revolution) TCN = SIO plus Modbus TCP without M12

01 = 0.1 inch (2.54 mm) HH = Feedback Type connector 9

02 = 0.2 inch (5.08 mm) HD = Analog Hall Device

04 = 0.4 inch (10.16 mm) (60 mm only) IE = Incremental Encoder, 8192 count resolution MM = Mechanical Options 5

05 = 0.5 inch (12.7 mm) (75 mm only) AF = Absolute Feedback 11 AR = External Anti-rotate

PF = Preloaded Follower 2

E = Connections III-II = Motor Stator, All 8 Pole L1/2/3 = External Limit Switches 6

G = Standard Straight Threaded Port with internal TDM/X060 Stator Specifications RB = Rear Brake

terminals, M20x1.5 (75 mm only) 1B8-50 = 1 Stack, 48 VDC, 5000 rpm HW = Manual Drive, Handwheel with Interlock

N = NPT Threaded Port via Adapter with Internal 2B8-50 = 2 Stack, 48 VDC, 5000 rpm Switch (TDX075 only)

Terminals, 1/2” NPT (75 mm only) 3B8-40 = 3 Stack, 48 VDC. 4000 rpm 4 PB = Protective Bellows 8

I = Intercontec Style - Exlar standard, SR = Splined Main Rod 7,10

M23 Style Connector

J = Embedded Leads, with “I” plug, 3 ft. standard

F = Mounting

C = Rear Clevis For options or specials not listed above or for

G = Metric Rear Clevis extended temperature operation, please contact Exlar

NOTES:

1. Chrome-plated carbon steel. Threads not 4. Not available on 0.1 inch lead. 9. Requires customer supplied Ethernet cable

chrome-plated. 5. For extended temperature operation consult through I/O port for Class 1 Division 2

2. The dynamic load rating of zero backlash, factory for model number. compliance only.

preloaded screws is 63% of the dynamic 6. Limit switch option requires AR option. 10. Consult Exlar if ordering splined stainless

load rating of the standard non-preloaded 7. This option is not sealed and is not suitable for steel main rod.

screws. The calculated travel life of any environment in which contaminants come 11. When ordering a TDM, RDM or RDG 60 mm

a preloaded screw will be 25% of the in contact with actuator and may enter the or other sizes with top mounted connectors

calculated travel life of the same size actuator. the battery backup for AF feedback must be

and lead of a non-pre loaded screw. 8. Not available with extended tie rod mounting mounted externally. A DIN rail mounted board

3. This housing option may indicate the need for option. and battery is supplied, Exlar PN 48224.

special material main rods or mounting.

112 952.500.6200 | www.exlar.com