Page 31 - Eaton - Automatic self-cleaning family

P. 31

////////////////////////

TECHNICAL INFORMATION

Tubular Backwashing Systems

Mechanically Cleaned Filters & Strainer

PressureTactics

Tubular backwashing systems

save you time and money

compared with disposable media

systems. The permanent media

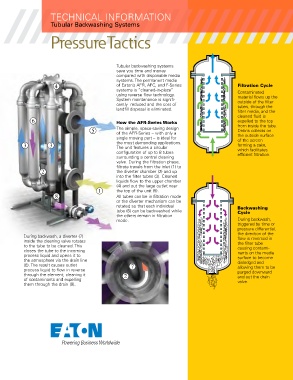

4 of Eaton’s AFR, AFC, and F-Series Filtration Cycle

systems is “cleaned-in-place” Contaminated

using reverse flow technology. material flows up the

System maintenance is signifi- outside of the filter

cantly reduced and the cost of tubes, through the

landfill disposal is eliminated. filter media, and the

cleaned fluid is

6 How the AFR-Series Works expelled to the top

from inside the tube.

5 The simple, space-saving design Debris collects on

of the AFR-Series – with only a the outside surface

single moving part – is ideal for of the screen

3 3 the most demanding applications. forming a cake,

The unit features a circular

configuration of up to 8 tubes which facilitates

efficient filtration.

surrounding a central cleaning

valve. During the filtration phase,

filtrate travels from the inlet (1) to

2 the diverter chamber (2) and up

into the filter tubes (3). Cleaned

liquids flow to the upper chamber

(4) and out the large outlet near

1 the top of the unit (5).

8 All tubes can be in filtration mode

or the diverter mechanism can be

rotated so that each individual Backwashing

tube (6) can be backwashed while Cycle

the others remain in filtration

mode. During backwash,

triggered by time or

pressure differential,

the direction of the

During backwash, a diverter (7) flow is reversed in

inside the cleaning valve rotates the filter tube

to the tube to be cleaned. This causing contami-

closes the tube to the incoming nants on the media

process liquid and opens it to surface to become

the atmosphere via the drain line dislodged and

(8). The result causes outlet 7 6 allowing them to be

process liquid to flow in reverse purged downward

through the element, cleaning it 2 and out the drain

of contaminants and expelling valve.

them through the drain (8).