Page 22 - Parker - Coils and Electronics

P. 22

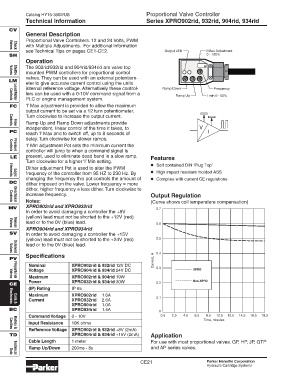

Catalog HY15-3502/US Proportional Valve Controller

Technical Information Series XPRO902rid, 932rid, 904rid, 934rid

CV

General Description

Proportional Valve Controllers. 12 and 24 Volts, PWM

with Multiple Adjustments. For additional information

see Technical Tips on pages CE1-CE2. Output LED I Max Adjustment

Check

Valves

SH 0 - 100%

Operation

The 902rid/932rid and 904rid/934rid are valve top

mounted PWM controllers for proportional control

Shuttle

Valves

valves. They can be used with an external potentiom-

LM

eter to give accurate current control using the units

internal reference voltage. Alternatively these control- Ramp Down Frequency

lers can be used with a 0-10V command signal from a

Ramp Up I min 0 - 50%

PLC or engine management system.

Load/Motor

Controls

FC ‘I’ Max adjustment is provided to allow the maximum

output current to be set via a 12 turn potentiometer.

Turn clockwise to increase the output current.

Ramp Up and Ramp Down adjustments provide

Flow

Controls

independent, linear control of the time it takes, to V

PC I

reach ‘I’ Max and to switch off, up to 8 seconds of

delay. Turn clockwise for slower ramps.

‘I’ Min adjustment Pot sets the minimum current the

controller will jump to when a command signal is

Pressure

Controls

LE present, used to eliminate dead band in a slow ramp. Features

Turn clockwise for a higher ‘I’ Min setting.

Dither adjustment Pot is used to alter the PWM • Self contained DIN ‘Plug Top’

frequency of the controller from 95 HZ to 230 Hz. By • High impact resistant molded ABS

Elements

changing the frequency this pot controls the amount of • Complies with current CE regulations

Logic

DC dither imposed on the valve. Lower frequency = more

dither, higher frequency = less dither. Turn clockwise to

increase frequency. Output Regulation

Notes: (Curve shows coil temperature compensation)

Directional

Controls

XPRO902rid and XPRO932rid

MV 0.7

In order to avoid damaging a controller the +8V

(yellow) lead must not be shorted to the +12V (red)

lead or to the 0V (blue) lead. 0.6

XPRO904rid and XPRO934rid

Manual

Valves

SV In order to avoid damaging a controller the +15V

(yellow) lead must not be shorted to the +24V (red) 0.5

lead or to the 0V (blue) lead.

Solenoid

Valves

Specifications 0.4

PV Current, A

Nominal XPRO902rid & 932rid 12V DC 0.3

Voltage XPRO904rid & 934rid 24V DC XPRO

Maximum XPRO902rid & 904rid 19W

Proportional

Valves

Power XPRO932rid & 934rid 30W 0.2 Non-XPRO

CE

(IP) Rating IP 65

Maximum XPRO902rid 1.6A

0.1

Current XPRO932rid 2.6A

XPRO904rid 1.0A

Coils &

Electronics

BC XPRO934rid 1.4A

0

Command Voltage 0 - 10V 0.5 2.5 4.5 6.5 8.5 10.5 12.5 14.5 16.5 18.5

Time, minutes

Input Resistance 10K ohms

Refference Voltage XPRO902rid & 932rid +8V (2mA)

Bodies &

Cavities

TD XPRO904rid & 934rid +15V (2mA) Application

Cable Length 1 meter For use with most proportional valves. GP, HP, JP, GTP

Ramp Up/Down 200ms - 8s and AP series valves.

Technical

Data

CE21 Parker Hannifin Corporation

Hydraulic Cartridge Systems