Page 3 - Parker - TruBind 300 Cartridges

P. 3

TruBind 300 Findings

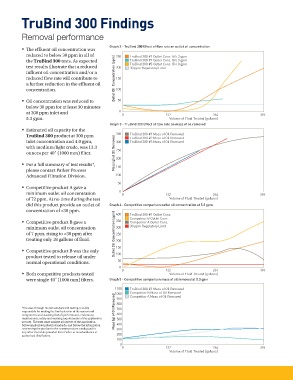

Removal performance

Graph 2 - TruBind 300 Effect of fl ow rate on outlet oil concentration

• Th e effl uent oil concentration was

reduced to below 30 ppm in all of 250 TruBind 300 #1 Outlet Conc. @ 5.3 gpm

the TruBind 300 tests. As expected TruBind 300 #2 Outlet Conc. @ 5.3 gpm

TruBind 300 #3 Outlet Conc. @ 4.0 gpm

test results illustrate that a reduced 200 30 ppm Regulatory Limit

infl uent oil concentration and/or a

reduced fl ow rate will contribute to Outlet Oil Concentration (ppm) 150

a further reduction in the effl uent oil

concentration. 100

• Oil concentration was reduced to 50

below 30 ppm for at least 30 minutes

at 300 ppm inlet and 0

0 132 264 396

5.3 gpm. Volume of Fluid Treated (gallons)

Graph 3 - TruBind 300 Effect of fl ow rate on mass of oil removed

• Estimated oil capacity for the

350 TruBind 300 #1 Mass of Oil Removed

TruBind 300 product at 300 ppm TruBind 300 #2 Mass of Oil Removed

inlet concentration and 4.0 gpm, 300 TruBind 300 #3 Mass of Oil Removed

with medium/light crude, was 13.3 250

ounces per 40" (1000 mm) fi lter. Mass (g) of Oil Removed 200

• For a full summary of test results*, 150

please contact Parker Process

Advanced Filtration Division. 100

50

• Competitive product A gave a

0

minimum outlet oil concentration 0 132 264 396

of 72 ppm. At no time during the test Volume of Fluid Treated (gallons)

did this product provide an outlet oil Graph 4 - Competitive comparison outlet oil concentration at 5.3 gpm

concentration of <30 ppm. 400 TruBind 300 #1 Outlet Conc.

• Competitive product B gave a 350 Competitor B Outlet Conc.

Competitor A Outlet Conc.

minimum outlet oil concentration 300 30 ppm Regulatory Limit

of 7 ppm, rising to >30 ppm after Outlet Oil Concentration (ppm) 250

treating only 18 gallons of fl uid. 200

• Competitive product B was the only 150

100

product tested to release oil under

50

normal operational conditions.

0

0 132 264 396

• Both competitive products tested Volume of Fluid Treated (gallons)

were single 40" (1000 mm) fi lters. Graph 5 - Competitive comparison mass of oil removed at 5.3 gpm

1100 TruBind 300 #1 Mass of Oil Removed

1000 Competitor B Mass of Oil Removed

Mass (g) of Oil Removed

Competitor A Mass of Oil Removed

900

*Th e user, through its own analysis and testing, is solely 800

700

responsible for making the fi nal selection of the system and

components and assuring that all performance, endurance, 600

maintenance, safety and warning requirements of the application 500

are met. Th e user must analyze all aspects of the application,

follow applicable industry standards, and follow the information 400

concerning the product in the current product catalog and in 300

any other materials provided from Parker or its subsidiaries or

authorized distributors. 200

100

0

0 132 264 396

Volume of Fluid Treated (gallons)