Page 172 - Mechatronics with Experiments

P. 172

158 MECHATRONICS

From the desired motion profile specification, we determine the maximum speed the

actuator must deliver using the kinematic relations. In order to design an optimal motion

control axis, the actuator sizing and the motion conversion mechanism (effective gear ratio)

should be considered together. It is possible that a very small gear ratio may require a motor

with very large torque requirement, and yet run at very low speeds, hence making use of a

small part of the power capacity of the motor. An increased gear ratio would then require a

smaller torque motor and that the motor would operate at higher speeds on average, hence

making more use of the available power of the motor.

Once the torque requirements are known, the drive current and power supply voltage

requirements can be directly determined for a given electric motor-drive system. Similarly,

for hydraulic actuators, once the force requirements are determined, we would pick the

supply pressure and determine the diameter of the linear cylinder. The speed requirement

would determine the flow rate. Once these are known, then the size of the valve and pump

can be determined.

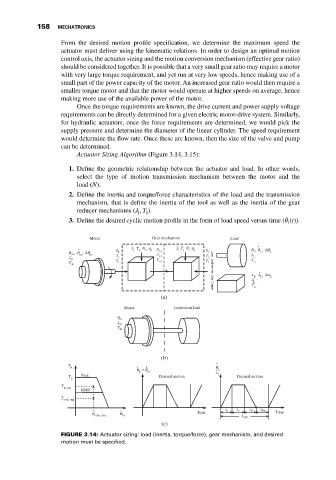

Actuator Sizing Algorithm (Figure 3.14, 3.15):

1. Define the geometric relationship between the actuator and load. In other words,

select the type of motion transmission mechanism between the motor and the

load (N).

2. Define the inertia and torque/force characteristics of the load and the transmission

mechanism, that is define the inertia of the tool as well as the inertia of the gear

reducer mechanisms (J , T ).

l

l

̇

3. Define the desired cyclic motion profile in the form of load speed versus time ( (t)).

l

Motor Gear mechanism Load

J T N η S J T N η ι θθ , Δθ

,

1 1

, θ , Δθ S L 1 1 i-1 i i i S i 1 L L

θ m J J

m m J i-1 J

T T T

J m L T i L

T m L i-1 i L

x , x , Δx L

1

L

J L

T

L

(a)

Motor Equivalent load

θ m

J m

T m

(b)

T

m θ

θ L = θ m x L

T p Peak Desired motion 1 Desired motion

T

p, req

RMS

T rms, req

t a t r t d t dw

θ θ Time Time

max, req m

t cyc

(c)

FIGURE 3.14: Actuator sizing: load (inertia, torque/force), gear mechanism, and desired

motion must be specified.