Page 32 - Mechatronics with Experiments

P. 32

JWST499-c01

18 JWST499-Cetinkunt Printer: Yet to Come October 9, 2014 7:39 254mm×178mm

MECHATRONICS

Ambient

air inlet

EGR

cooler

EGR Trap Turbine

valve

wheel Turbine exhaust

gas outlet

Ambient Turbo charger

air

section Exhaust

back pressure

valve Exhaust gas inlet

Waste gate Compressed

Compressor Turbine valve Ambient air discharge

air inlet

Compressor

Cool Inter wheel

air/water cooler

Engine block

Intake manifold

Cylinders Exhaust

gas

Exhaust manifold

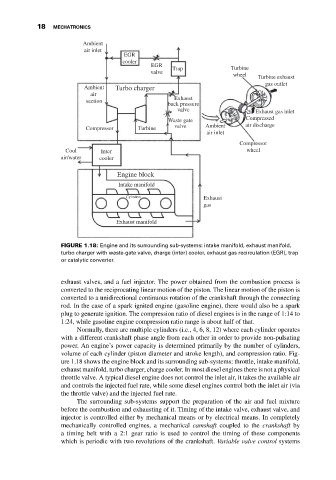

FIGURE 1.18: Engine and its surrounding sub-systems: intake manifold, exhaust manifold,

turbo charger with waste-gate valve, charge (inter) cooler, exhaust gas recirculation (EGR), trap

or catalytic converter.

exhaust valves, and a fuel injector. The power obtained from the combustion process is

converted to the reciprocating linear motion of the piston. The linear motion of the piston is

converted to a unidirectional continuous rotation of the crankshaft through the connecting

rod. In the case of a spark ignited engine (gasoline engine), there would also be a spark

plug to generate ignition. The compression ratio of diesel engines is in the range of 1:14 to

1:24, while gasoline engine compression ratio range is about half of that.

Normally, there are multiple cylinders (i.e., 4, 6, 8, 12) where each cylinder operates

with a different crankshaft phase angle from each other in order to provide non-pulsating

power. An engine’s power capacity is determined primarily by the number of cylinders,

volume of each cylinder (piston diameter and stroke length), and compression ratio. Fig-

ure 1.18 shows the engine block and its surrounding sub-systems: throttle, intake manifold,

exhaust manifold, turbo charger, charge cooler. In most diesel engines there is not a physical

throttle valve. A typical diesel engine does not control the inlet air, it takes the available air

and controls the injected fuel rate, while some diesel engines control both the inlet air (via

the throttle valve) and the injected fuel rate.

The surrounding sub-systems support the preparation of the air and fuel mixture

before the combustion and exhausting of it. Timing of the intake valve, exhaust valve, and

injector is controlled either by mechanical means or by electrical means. In completely

mechanically controlled engines, a mechanical camshaft coupled to the crankshaft by

a timing belt with a 2:1 gear ratio is used to control the timing of these components

which is periodic with two revolutions of the crankshaft. Variable valve control systems