Page 34 - Mechatronics with Experiments

P. 34

JWST499-Cetinkunt

JWST499-c01

20 MECHATRONICS Printer: Yet to Come October 9, 2014 7:39 254mm×178mm

System components

High-pressure oil manifold

High pressure

oil pump

HEUI

Fuel return line

RPCV

Fuel

filter

Fuel

ECM

Oil pump transfer

pump

Oil Oil

filter cooler Oil Fuel

sump tank

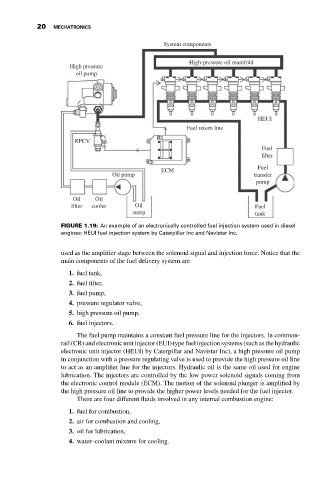

FIGURE 1.19: An example of an electronically controlled fuel injection system used in diesel

engines: HEUI fuel injection system by Caterpillar Inc and Navistar Inc.

used as the amplifier stage between the solenoid signal and injection force. Notice that the

main components of the fuel delivery system are

1. fuel tank,

2. fuel filter,

3. fuel pump,

4. pressure regulator valve,

5. high pressure oil pump,

6. fuel injectors.

The fuel pump maintains a constant fuel pressure line for the injectors. In common-

rail (CR) and electronic unit injector (EUI) type fuel injection systems (such as the hydraulic

electronic unit injector (HEUI) by Caterpillar and Navistar Inc), a high pressure oil pump

in conjunction with a pressure regulating valve is used to provide the high pressure oil line

to act as an amplifier line for the injectors. Hydraulic oil is the same oil used for engine

lubrication. The injectors are controlled by the low power solenoid signals coming from

the electronic control module (ECM). The motion of the solenoid plunger is amplified by

the high pressure oil line to provide the higher power levels needed for the fuel injector.

There are four different fluids involved in any internal combustion engine:

1. fuel for combustion,

2. air for combustion and cooling,

3. oil for lubrication,

4. water–coolant mixture for cooling.